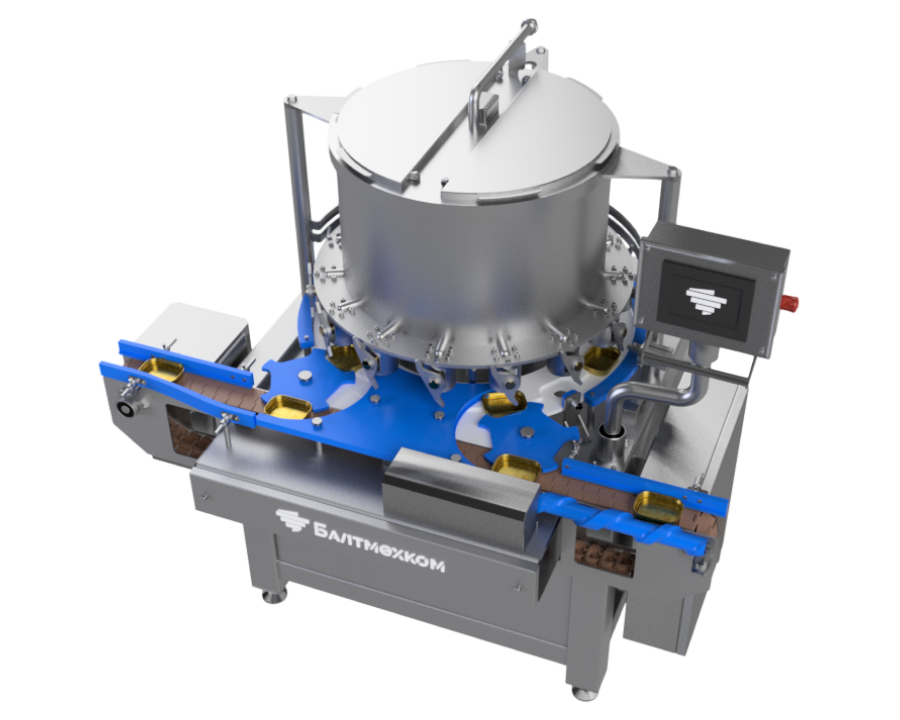

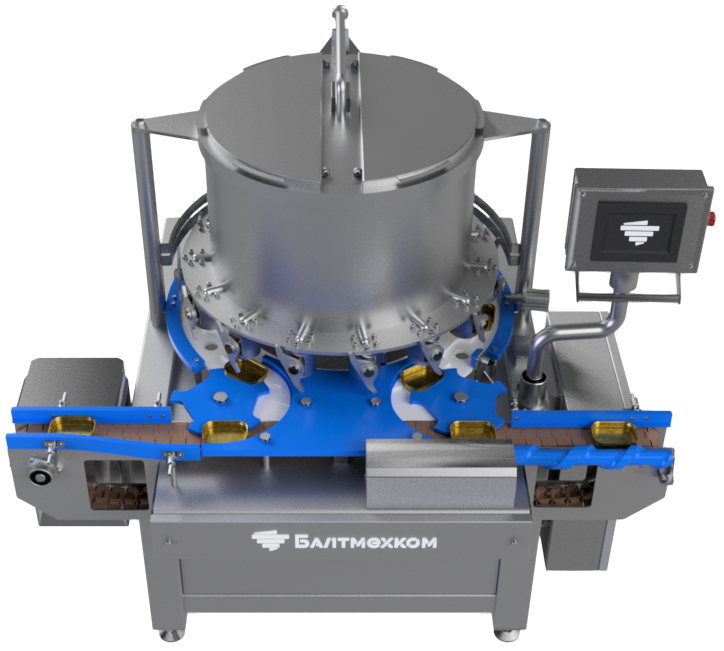

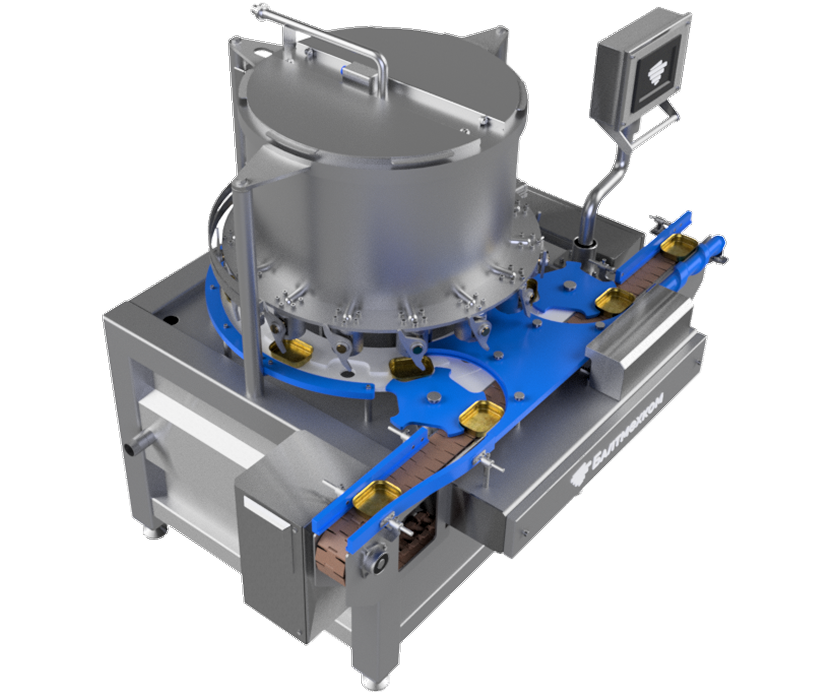

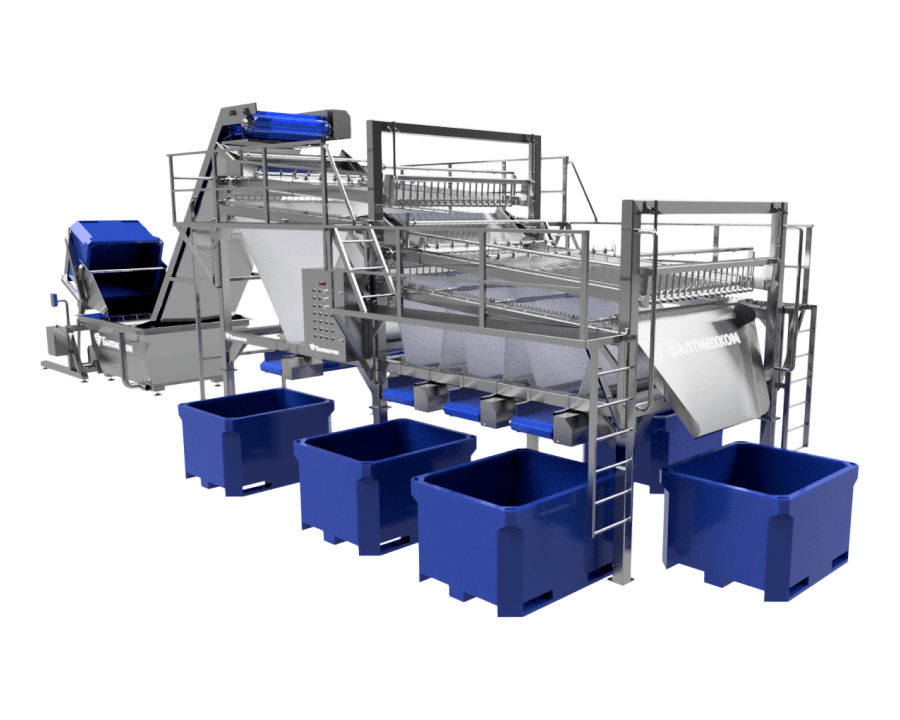

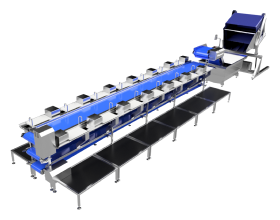

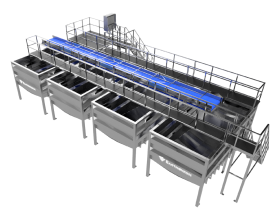

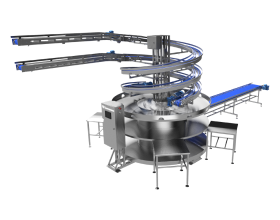

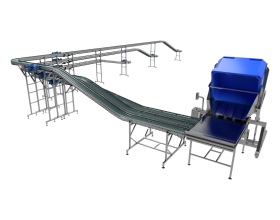

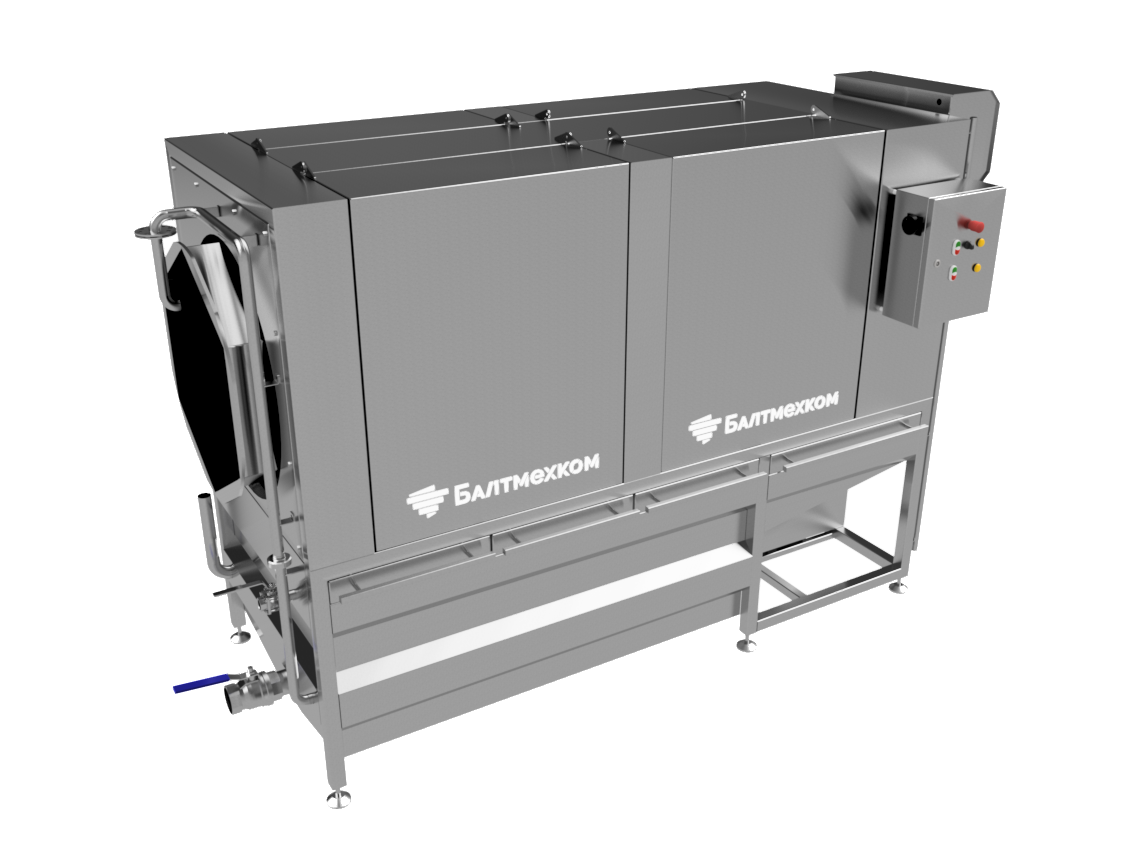

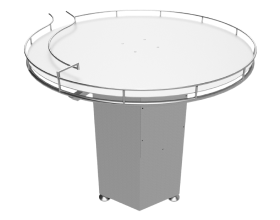

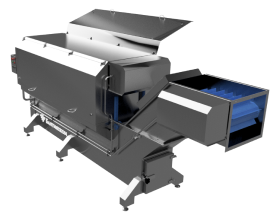

Rotary filling machine

Rotary filling machine

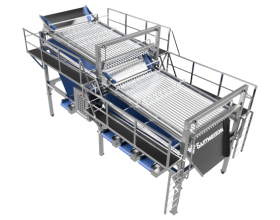

The device is integrated into canning production lines and is designed for dosing oil and sauce into cans.

Includes:

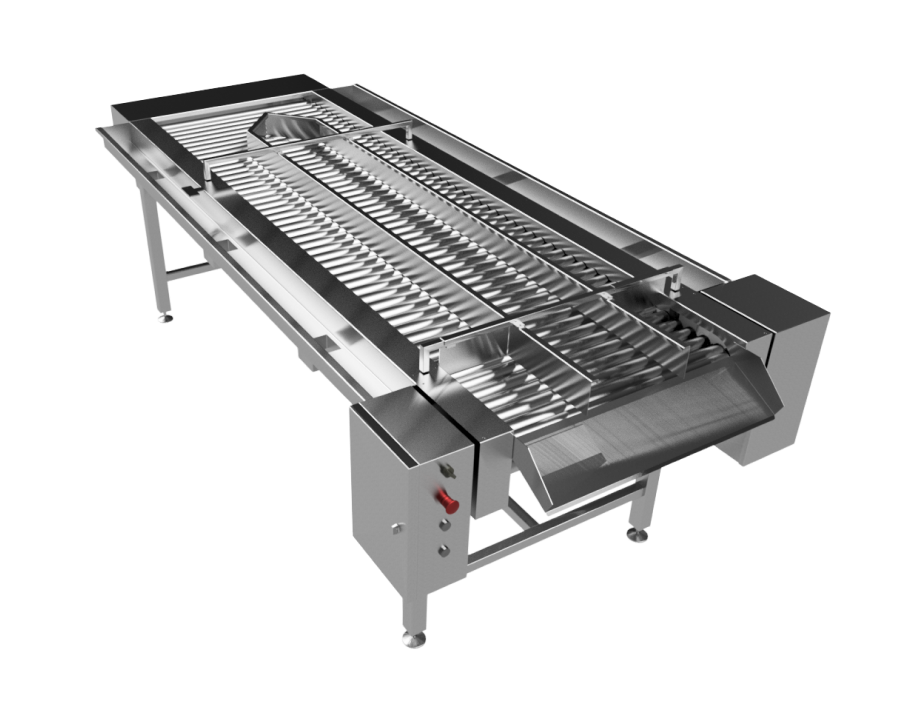

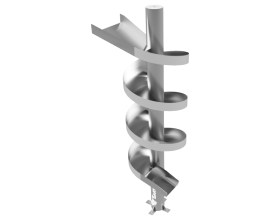

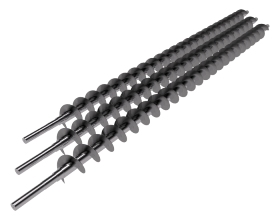

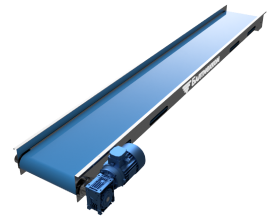

— Built-in conveyor with auger divider for round and shaped cans

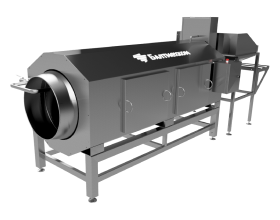

— Working tank with dosing units and a can carousel

— Dosing unit body with rotor and dividing element drive

— Temperature, level, and can presence sensors

— Quick dose adjustment

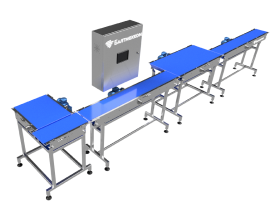

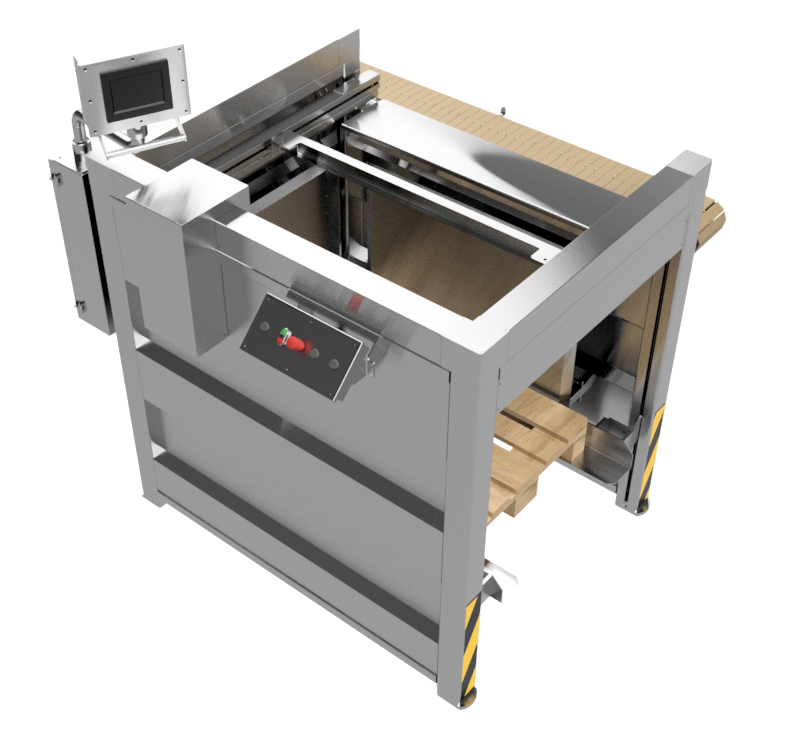

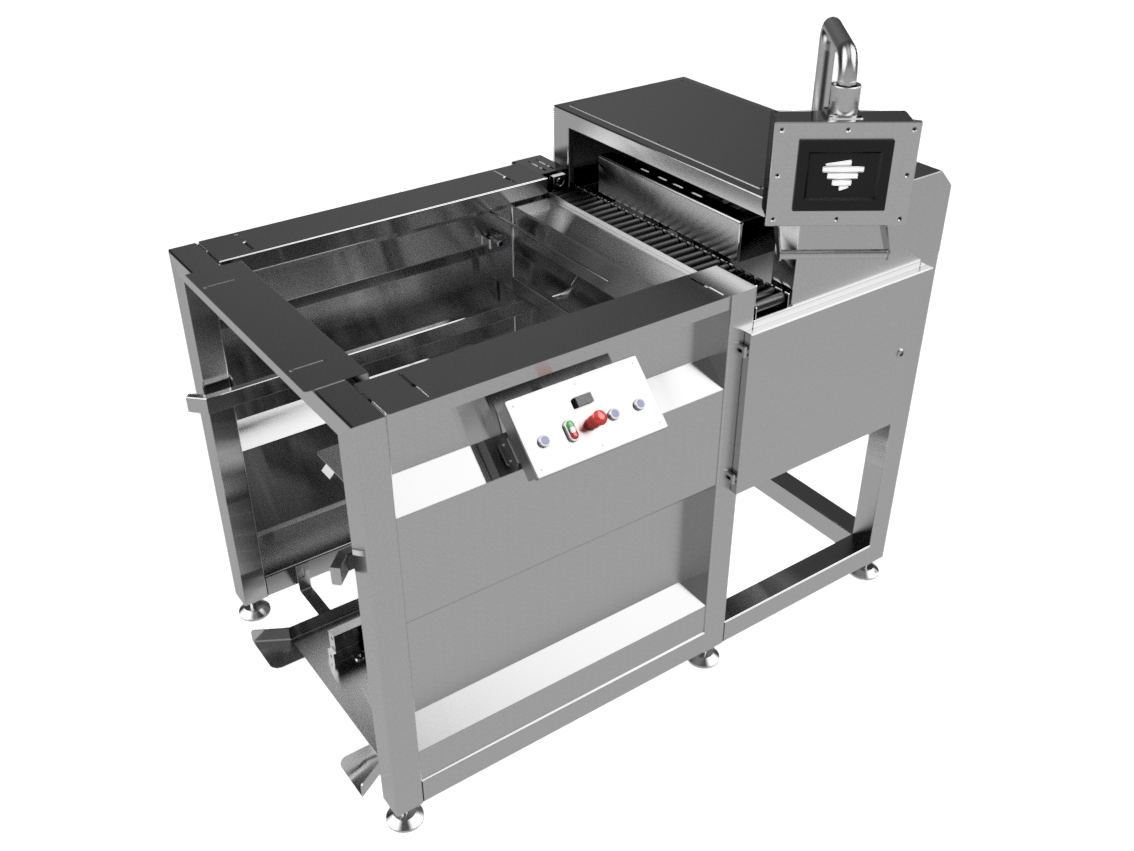

Touch control panel:

— Product temperature indication

— Product level indication and maintenance

— Productivity indication and adjustment

— Conveyor speed indication and adjustment

— Can counter

— Device wash function (open valves when no can is present)

The device is integrated into canning production lines and is designed for dosing oil and sauce into cans.

Includes:

— Built-in conveyor with auger divider for round and shaped cans

— Working tank with dosing units and a can carousel

— Dosing unit body with rotor and dividing element drive

— Temperature, level, and can presence sensors

— Quick dose adjustment

Touch control panel:

— Product temperature indication

— Product level indication and maintenance

— Productivity indication and adjustment

— Conveyor speed indication and adjustment

— Can counter

— Device wash function (open valves when no can is present)

| METRIC | TARGET |

|---|---|

| Productivity, up to | 220 can/min |

| Dosing range, ml | 5-100 |

| Dosing accuracy, ml | 0.5 |

| Dimensions: LxWxH, mm | 1700x1100x1550 |

| Power supply, V | 380 |

| Housing material | AISI 304 |

| Maximum temperature, °C | 70 |

| Hopper volume (geometric), l | 150 |

| Dosing unit | 15 |

| Air pressure, kg/cm2 | 6 |

| Total weight at least, kg | 600 |

RUS

RUS