Vegetable Processing Line

Vegetable Processing Line

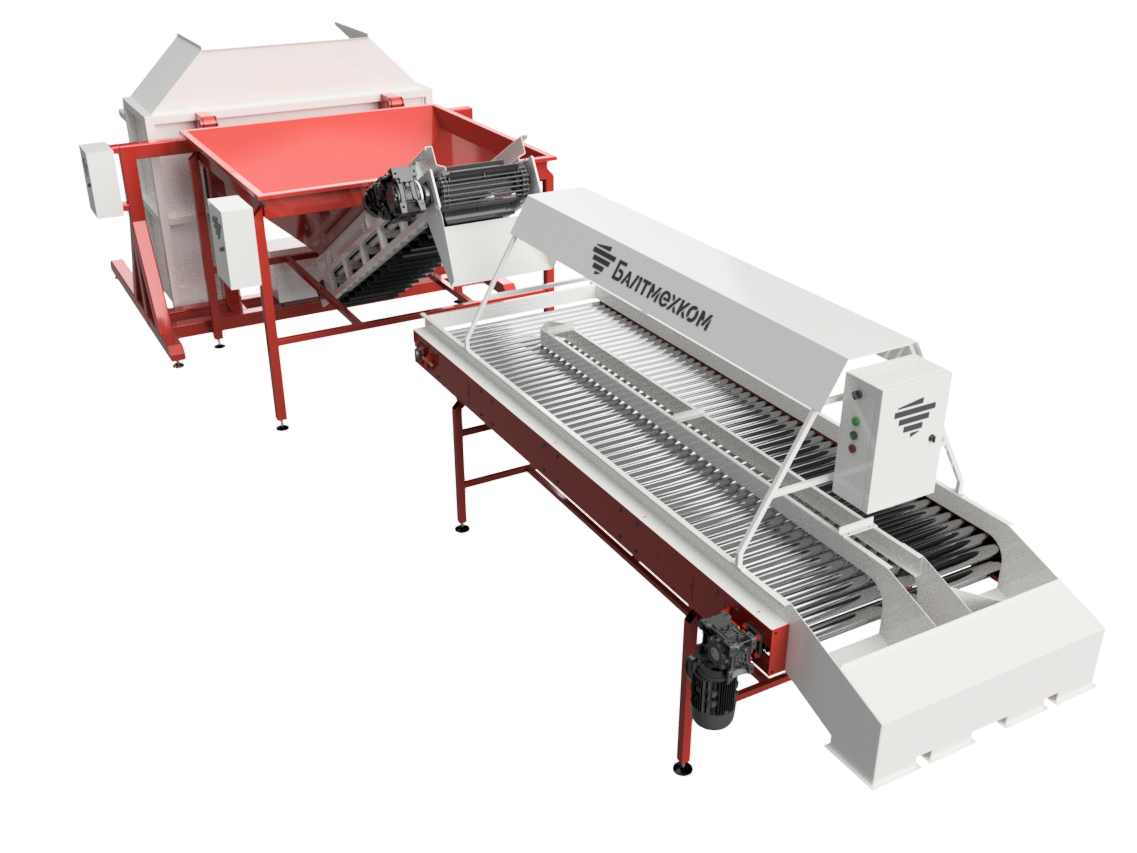

It consists of a container tipper, a hopper-dispenser and a roller inspection conveyor.

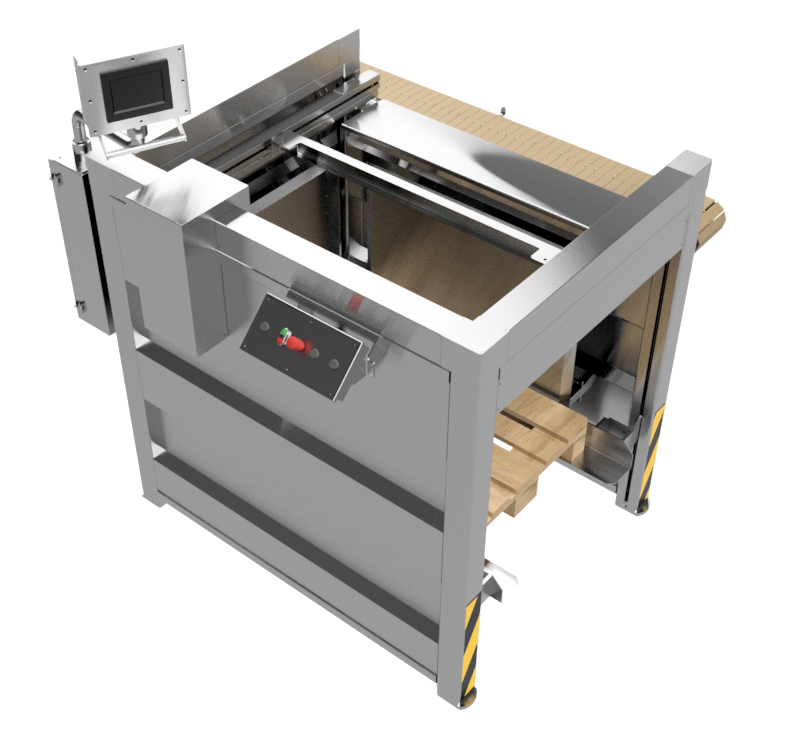

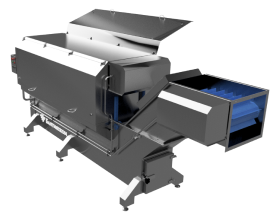

The tipper is designed for unloading the contents of containers in the hopper-dispenser.

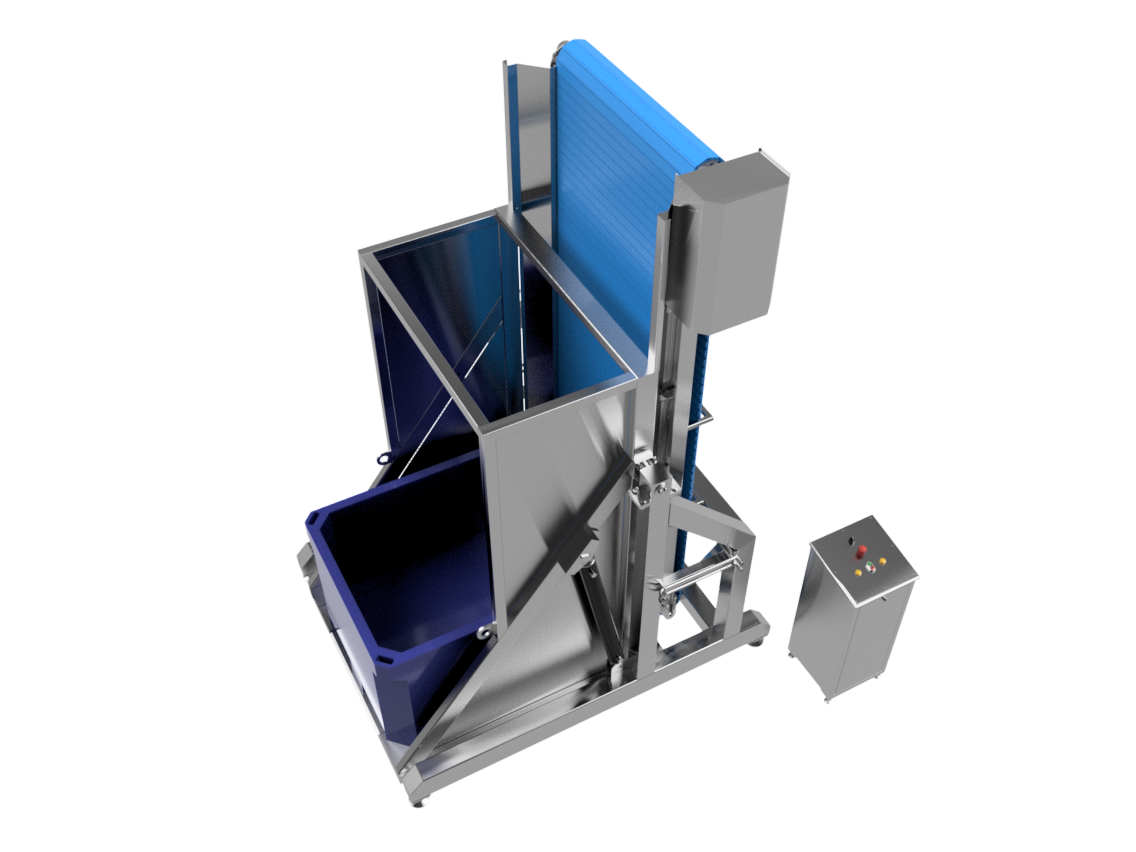

The device consists of a receiving hopper and a discharge conveyor. The hopper performs the function of an intermediate accumulator, and a scraper conveyor with a rod web doses the product and allows u to separate the earth during the movement of the conveyor.

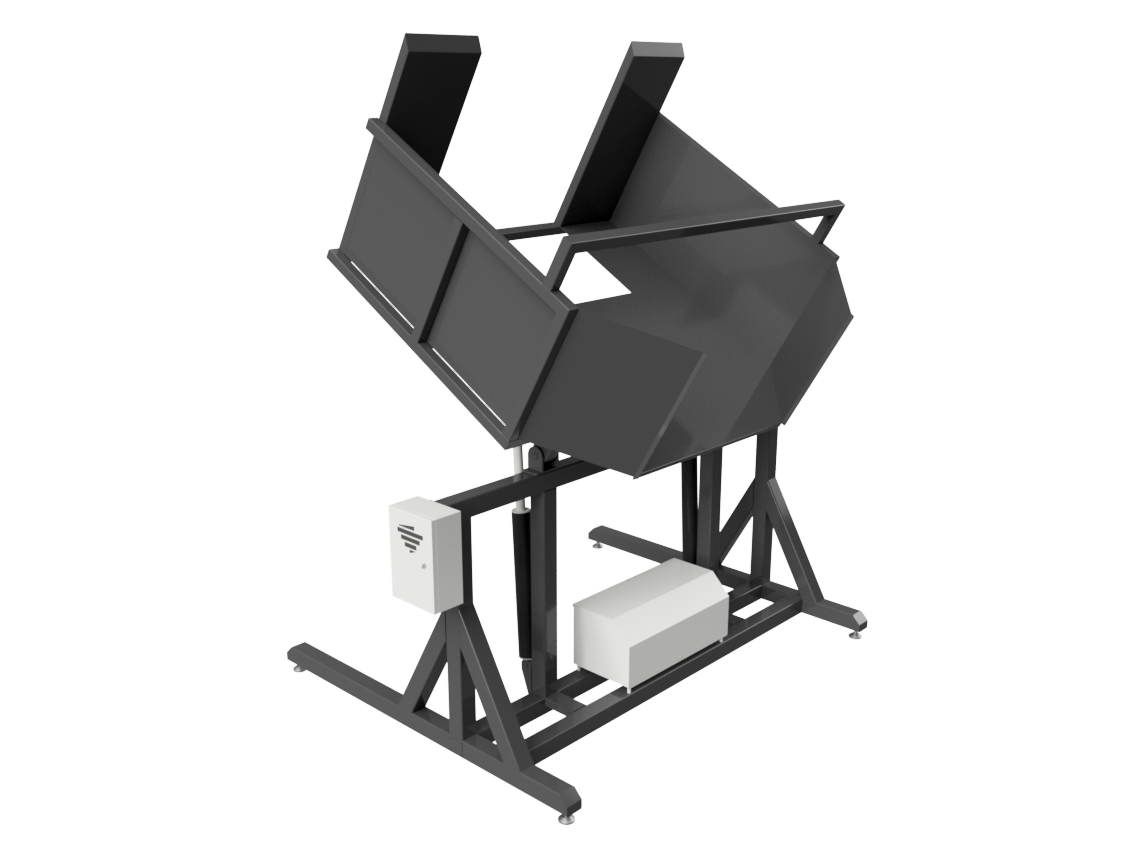

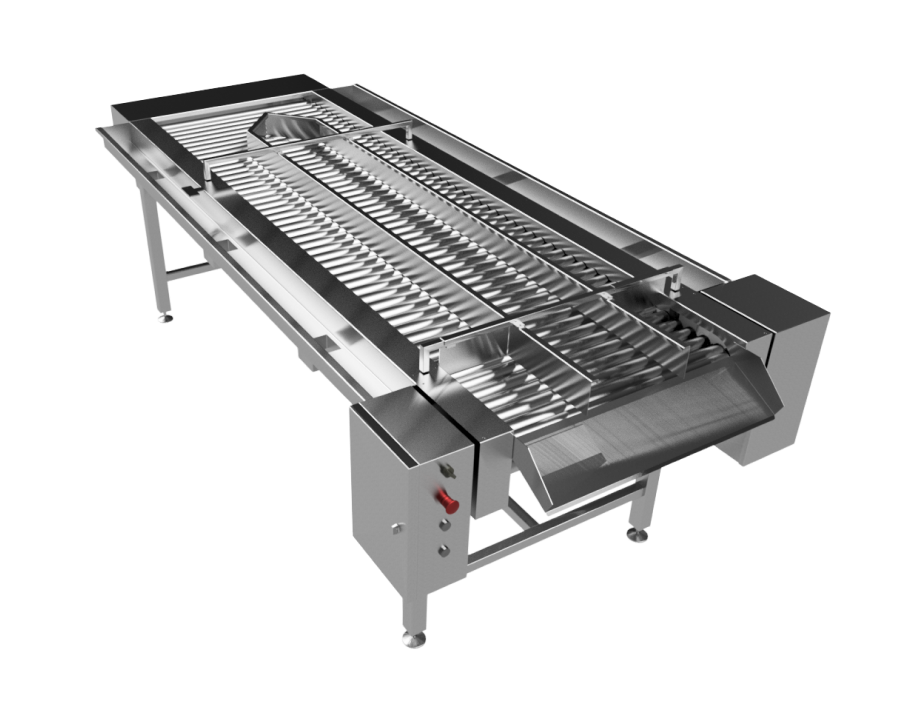

Inspection roller conveyor is designed to control the quality of vegetables; low-quality and non-standard products are separated manually.

Product (e.g. potatoes) enters the front of the conveyor. Due to the rotation of the rollers, the product turns over and advances along the belt, which allows the operator to control the quality. The rejected product is placed in the middle part of the conveyor, a good product enters the trays dispensers for packaging.

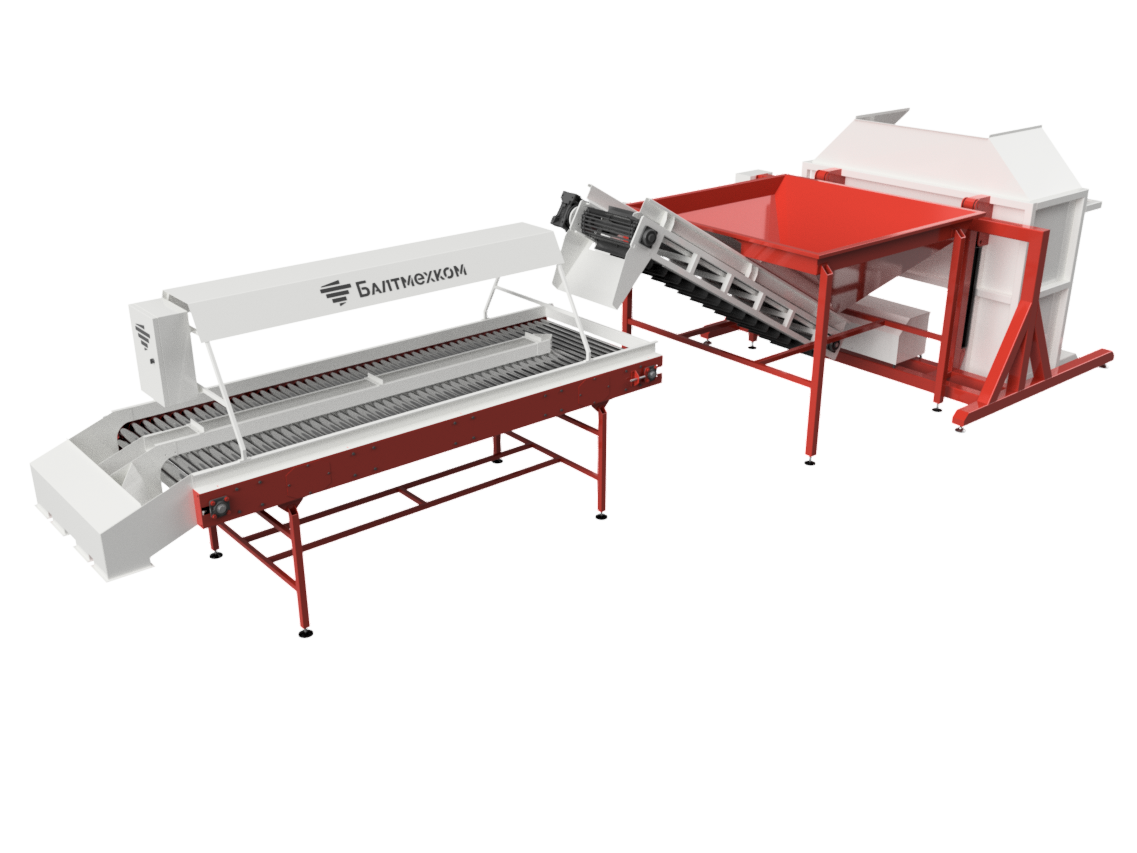

It consists of a container tipper, a hopper-dispenser and a roller inspection conveyor.

The tipper is designed for unloading the contents of containers in the hopper-dispenser.

The device consists of a receiving hopper and a discharge conveyor. The hopper performs the function of an intermediate accumulator, and a scraper conveyor with a rod web doses the product and allows u to separate the earth during the movement of the conveyor.

Inspection roller conveyor is designed to control the quality of vegetables; low-quality and non-standard products are separated manually.

Product (e.g. potatoes) enters the front of the conveyor. Due to the rotation of the rollers, the product turns over and advances along the belt, which allows the operator to control the quality. The rejected product is placed in the middle part of the conveyor, a good product enters the trays dispensers for packaging.

RUS

RUS