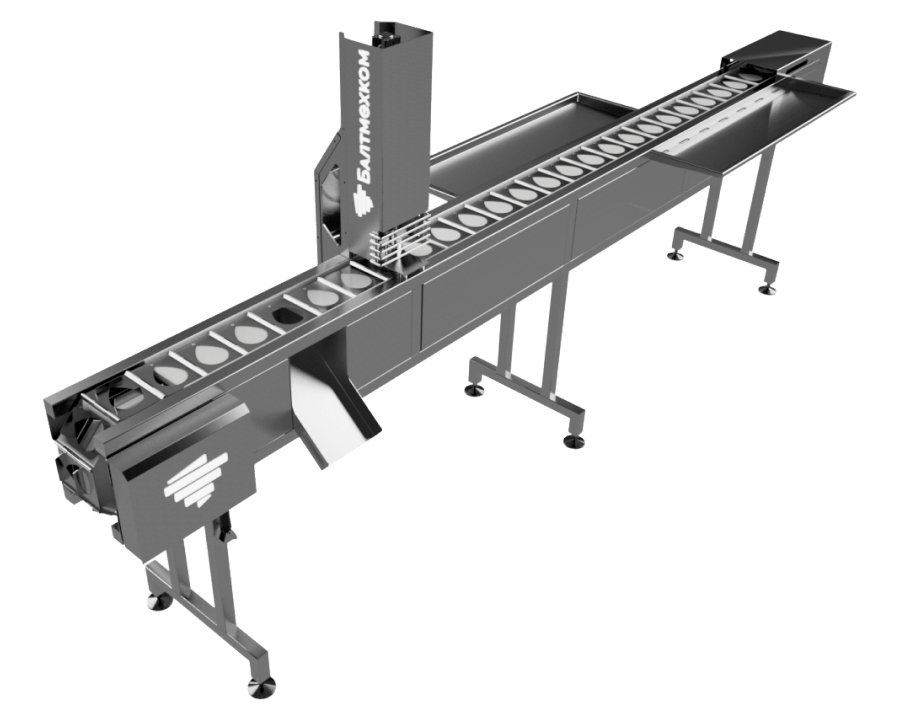

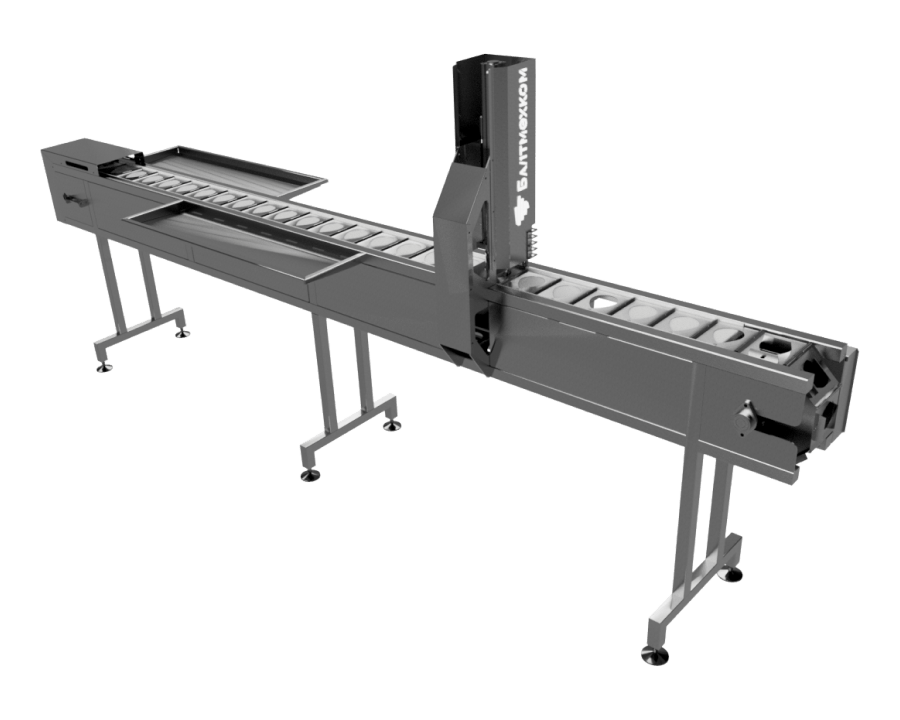

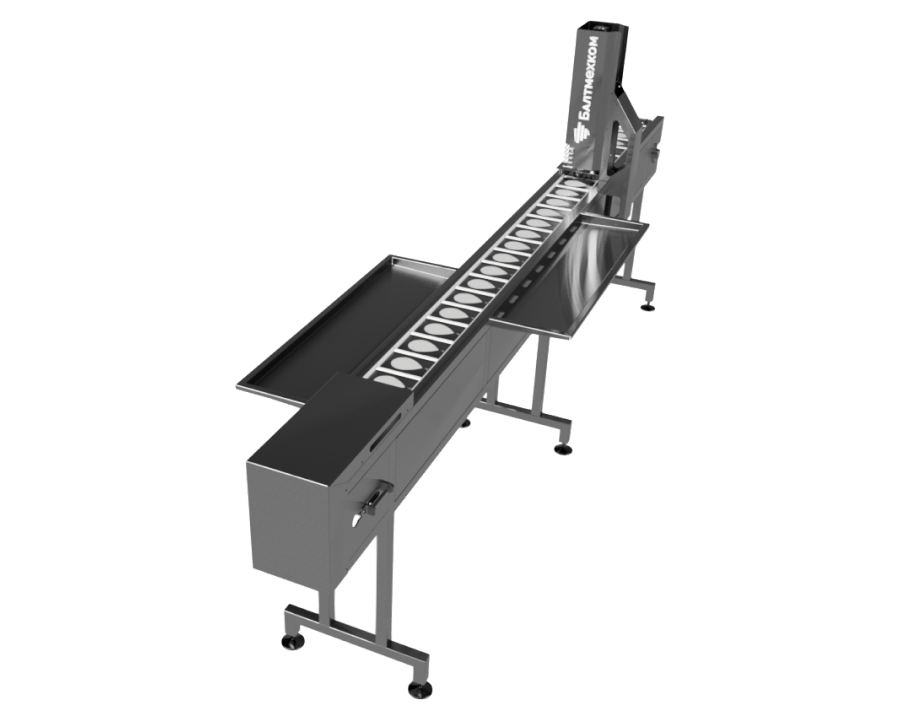

Fillet shaping device

Fillet shaping device

The principle of operation and technical characteristics;

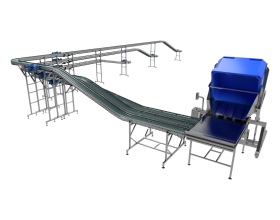

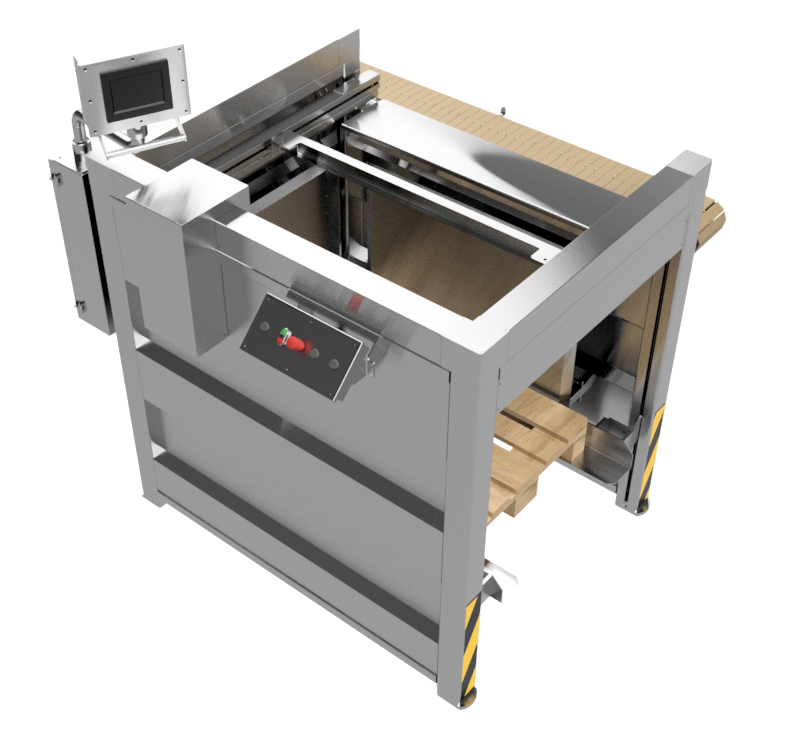

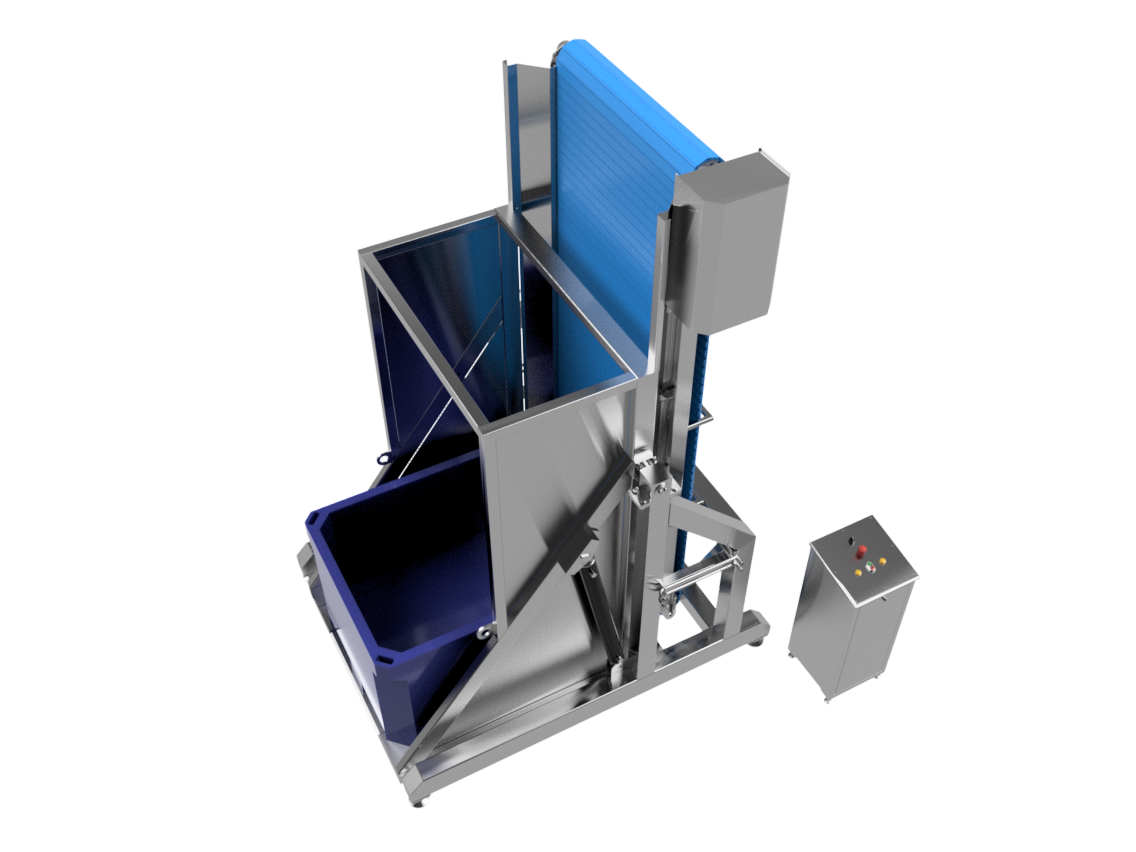

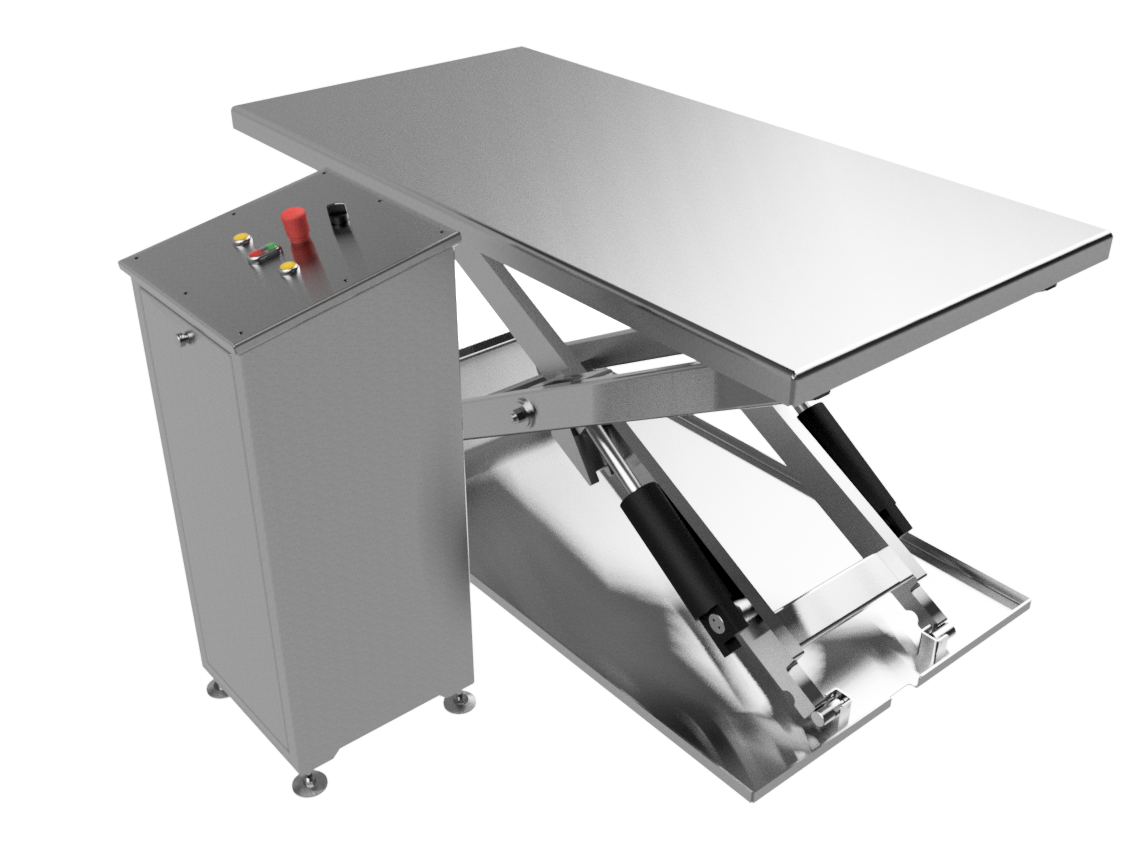

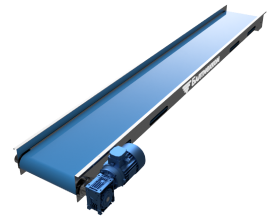

The device consists of a pneumatic cut-off mechanism, a stepper-driven conveyor feeder, a control panel and a frame with work tables. Operators place the fillet on the conveyor chain feeder so that the holes in the chain were blocked. Pneumatic conveyor-feeder provides cyclical filing in the forming area. After cutting off in the forming zone, the formed fillet with scraps enters the separation zone, where the finished fillet falls under its weight through an opening in the substrate of the conveyor into the container for the finished product, and the cuts move further along the conveyor into the container for waste. The pneumatic drive of the punch is synchronized with the pitch of the conveyor, which allows, by changing the feed rate, to adjust the performance of the device.

The principle of operation and technical characteristics;

The device consists of a pneumatic cut-off mechanism, a stepper-driven conveyor feeder, a control panel and a frame with work tables. Operators place the fillet on the conveyor chain feeder so that the holes in the chain were blocked. Pneumatic conveyor-feeder provides cyclical filing in the forming area. After cutting off in the forming zone, the formed fillet with scraps enters the separation zone, where the finished fillet falls under its weight through an opening in the substrate of the conveyor into the container for the finished product, and the cuts move further along the conveyor into the container for waste. The pneumatic drive of the punch is synchronized with the pitch of the conveyor, which allows, by changing the feed rate, to adjust the performance of the device.

| METRIC | TARGET |

|---|---|

| Working air pressure | 6 – 8 kg/cm² |

| Air consumption | 60 l/min |

| Overall dimensions | 2500×600×1500 mm |

| Productivity | 30 – 40 pcs/min |

| Case material | stainless steel |

RUS

RUS