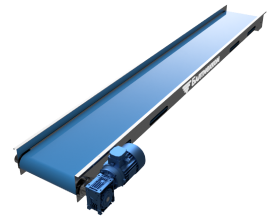

Narrow belt sorter

Narrow belt sorter

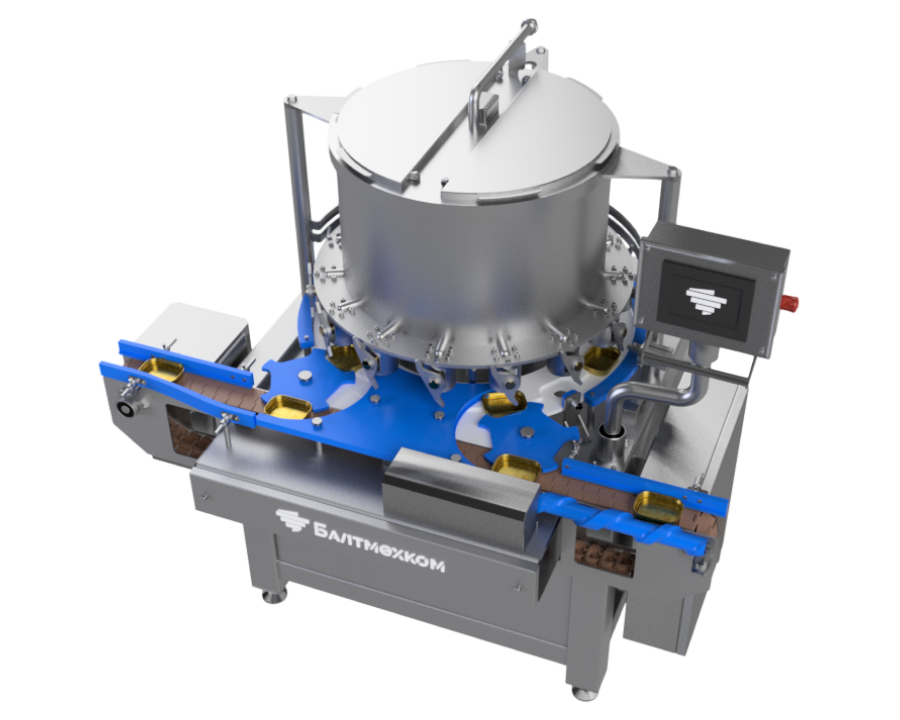

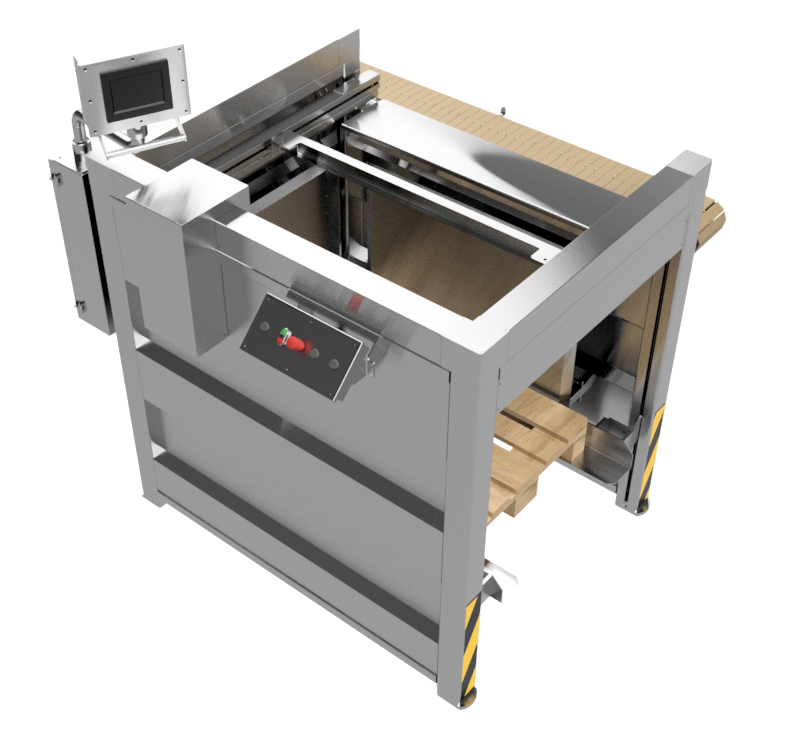

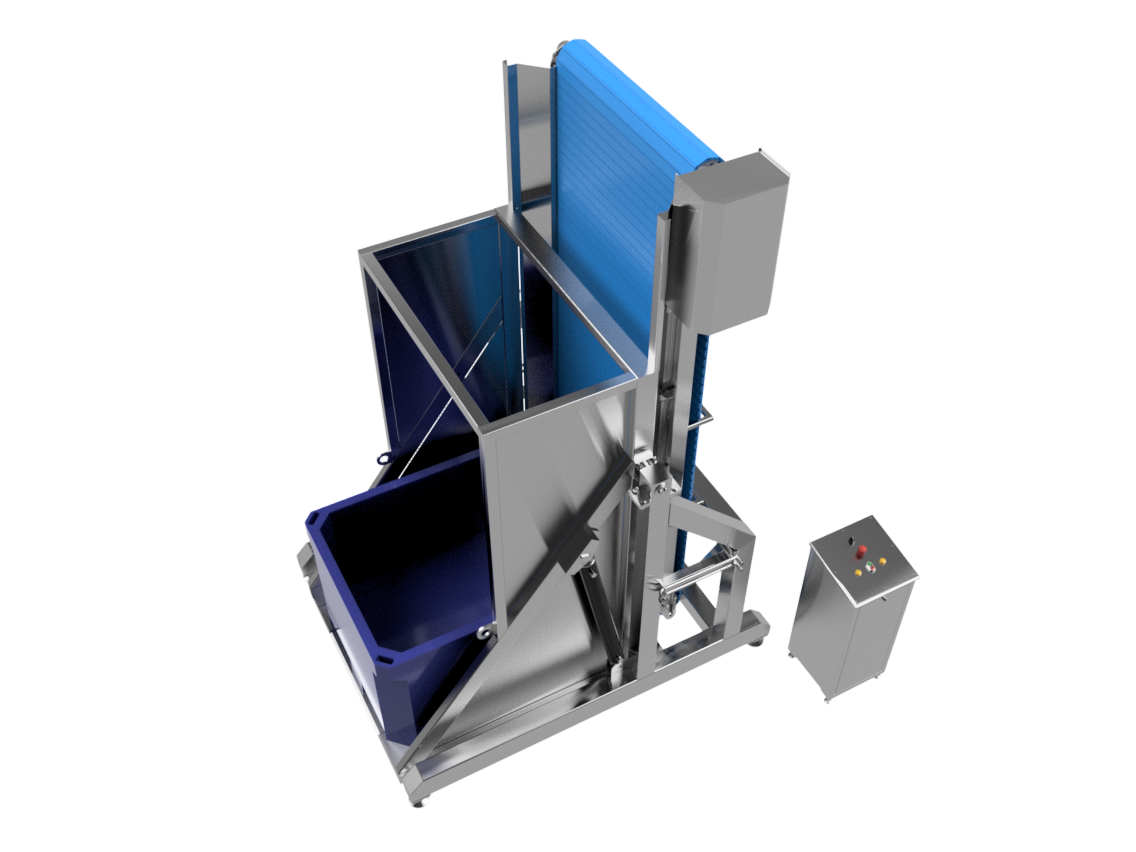

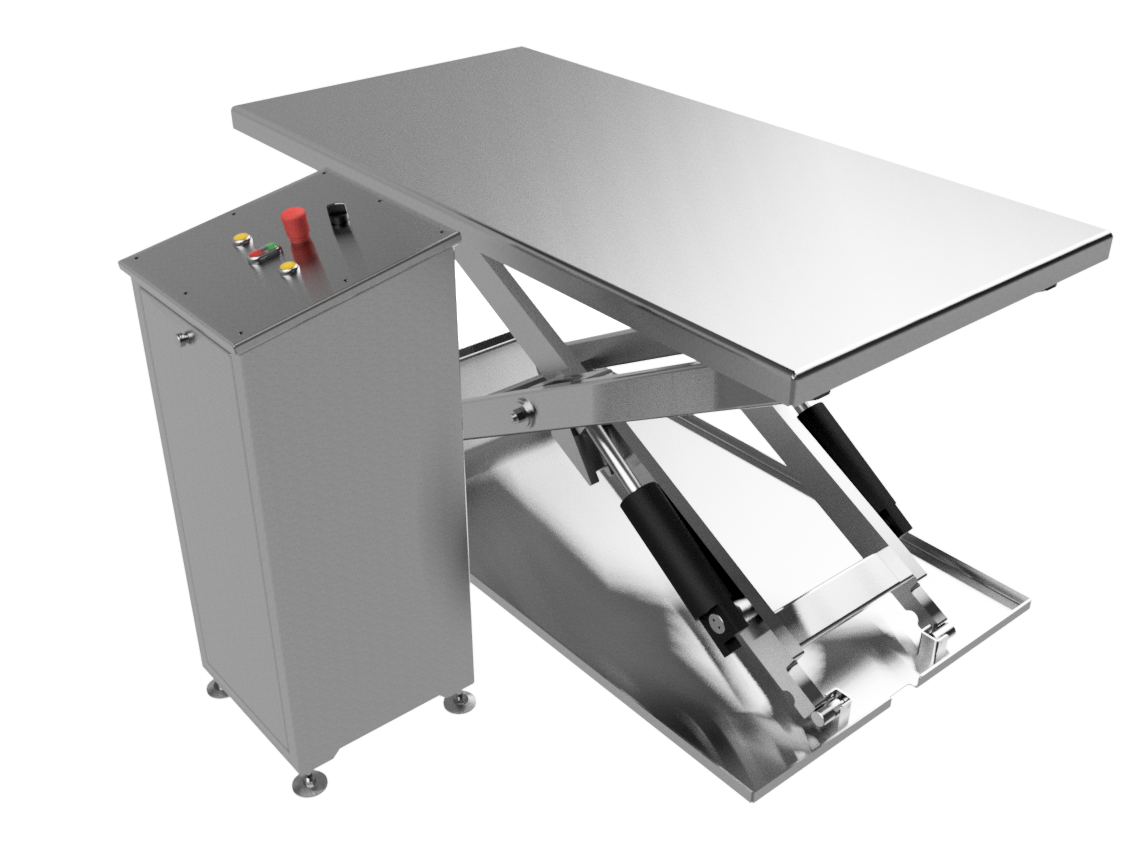

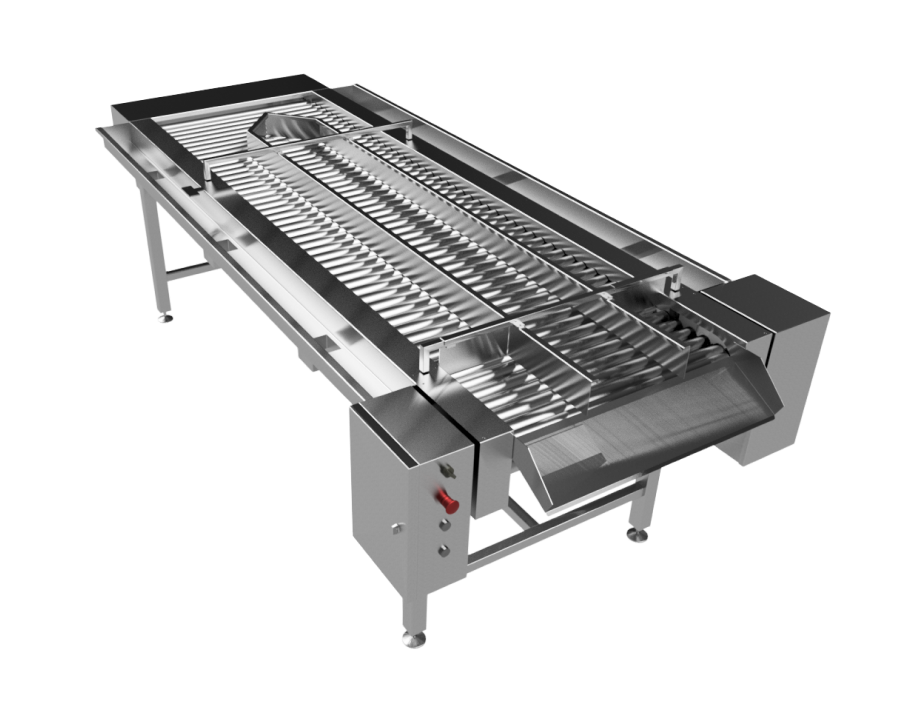

The device is used to change the direction of movement of the product (box) at 90 degrees, integrated in existing conveyor lines. Used in places where space is limited and relatively high bandwidth is required. The device can be used to sort the product according to various criteria, as well as to unload the main conveyor line during congestion and stops.

Principle of operation:

When overloading or stopping of the subsequent conveyor line, the system of withdrawing the boxes to the side is activated without stopping the main line. When object availability sensors are triggered, a certain time delay is triggered / lifted by the outlet roller table built into the belt conveyor. Next, the box enters the discharge line or to the cumulative roller conveyor for subsequent manual palletizing.

Benefits:

— Safety: the closed case, degree of protection of electric equipment conforms to the IP65 standard

-Compact design: stainless steel construction, built-in lifting roller table and removable body panels for easy access to machine components

-Universality: the ability to work with a box of various sizes. The use of three modes of operation and the possibility of programming for certain tasks

-Performance: high performance due to the use of a stepper motor and pneumatic drive in the outlet roller table

-Easy management: intuitive menu on the control panel

— Reliability: the use of high-quality components from leading manufacturers guarantees a long service life and excellent value for money.

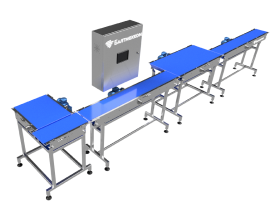

The device is used to change the direction of movement of the product (box) at 90 degrees, integrated in existing conveyor lines. Used in places where space is limited and relatively high bandwidth is required. The device can be used to sort the product according to various criteria, as well as to unload the main conveyor line during congestion and stops.

Principle of operation:

When overloading or stopping of the subsequent conveyor line, the system of withdrawing the boxes to the side is activated without stopping the main line. When object availability sensors are triggered, a certain time delay is triggered / lifted by the outlet roller table built into the belt conveyor. Next, the box enters the discharge line or to the cumulative roller conveyor for subsequent manual palletizing.

Benefits:

— Safety: the closed case, degree of protection of electric equipment conforms to the IP65 standard

-Compact design: stainless steel construction, built-in lifting roller table and removable body panels for easy access to machine components

-Universality: the ability to work with a box of various sizes. The use of three modes of operation and the possibility of programming for certain tasks

-Performance: high performance due to the use of a stepper motor and pneumatic drive in the outlet roller table

-Easy management: intuitive menu on the control panel

— Reliability: the use of high-quality components from leading manufacturers guarantees a long service life and excellent value for money.

RUS

RUS