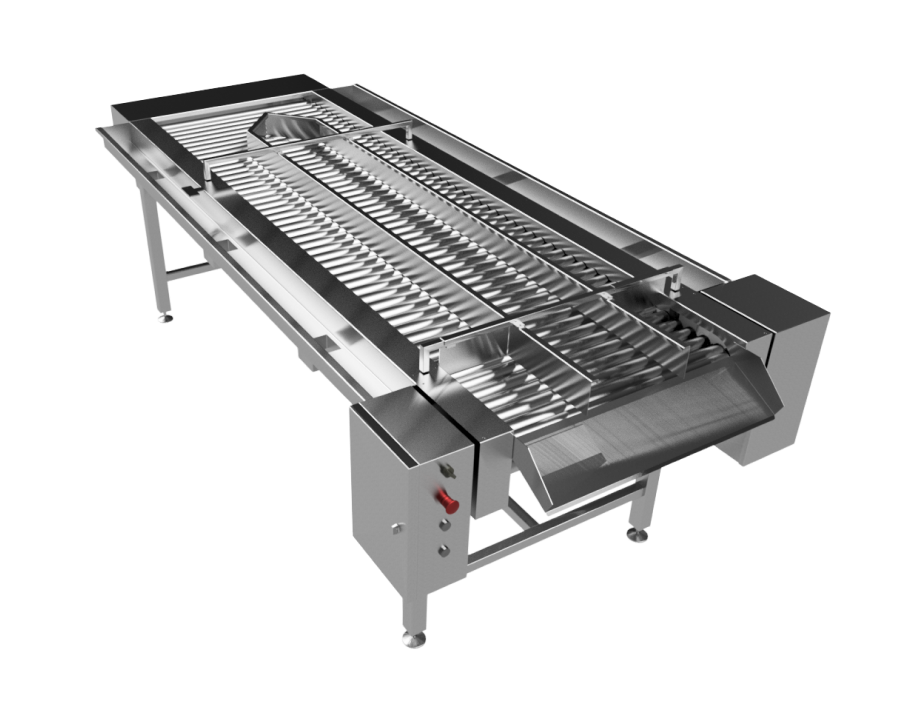

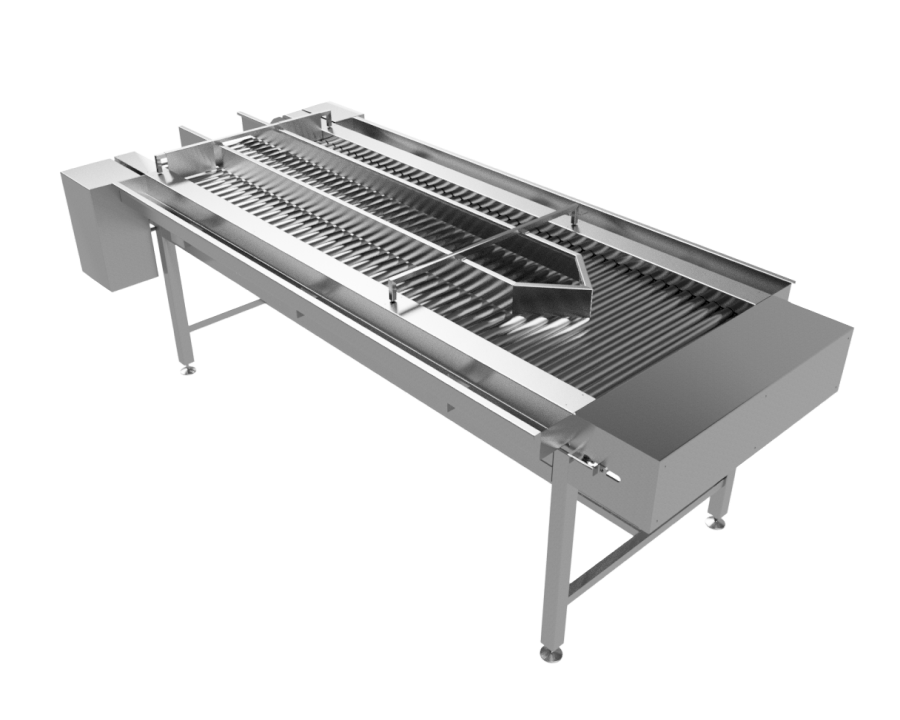

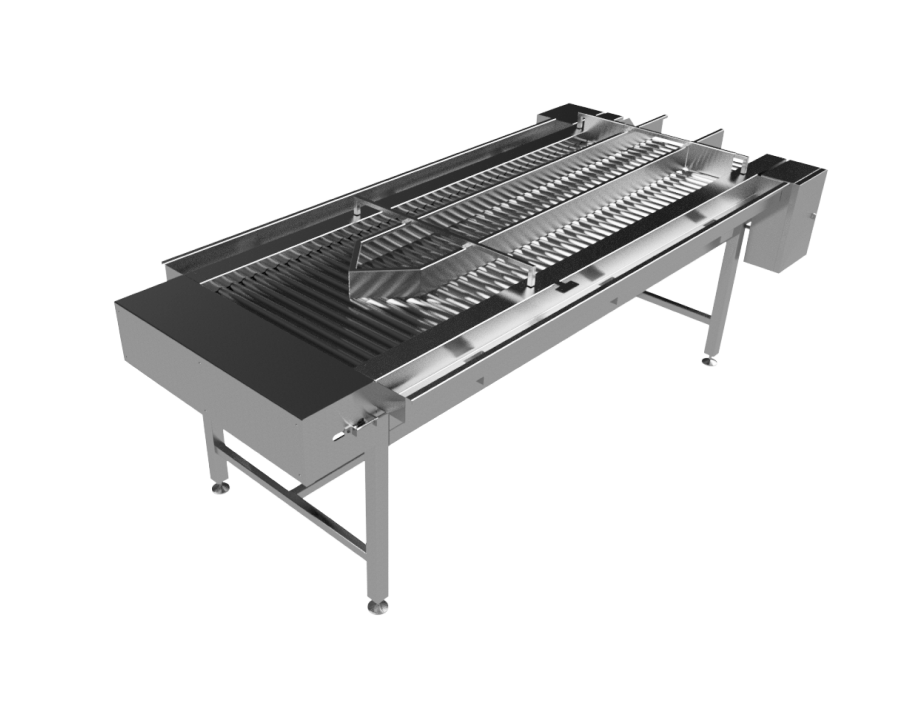

Inspection roller conveyor

Inspection roller conveyor

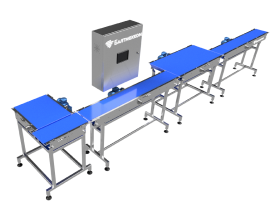

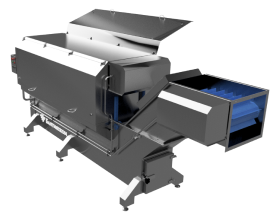

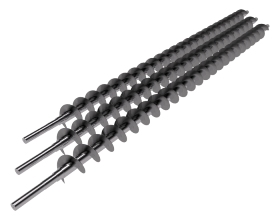

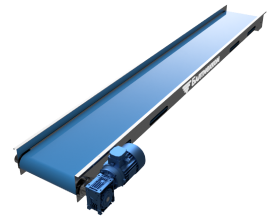

Roller inspection conveyor is designed to control the quality of the product. The quality control of the incoming product is carried out by mechanical (manual) separation of low-quality and non-standard products. The design is made entirely of stainless steel. Equipped with removable trays for waste disposal. Easy access to all parts of the mechanism for sanitization is provided.

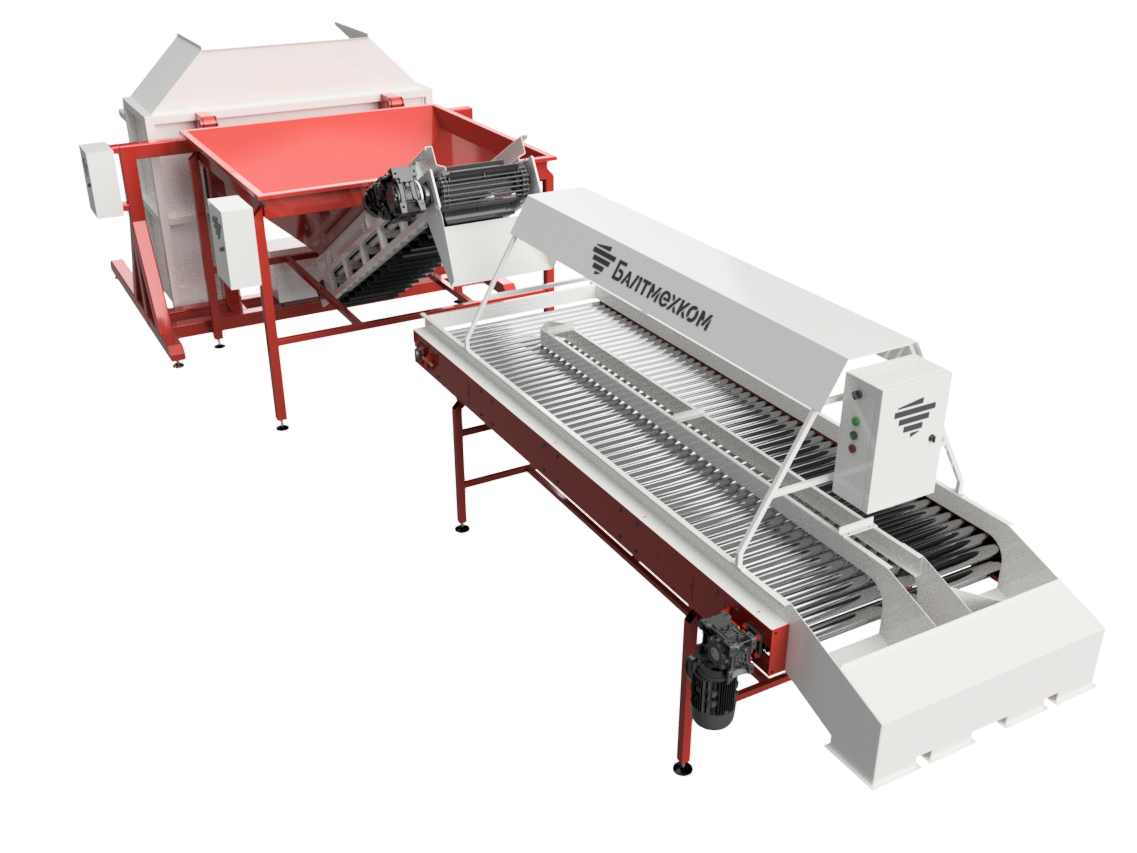

Application: the machine can be used autonomously, as well as be integrated into technological lines for processing vegetables, for inspection and rejection of the product.

Operating principle ;

The product (for example, peeled potatoes) enters the front of the conveyor. Due to the rotation of the rollers, the product turns over and moves in the direction of the tape, which allows the operator to control the quality of cleaning.

Roller inspection conveyor is designed to control the quality of the product. The quality control of the incoming product is carried out by mechanical (manual) separation of low-quality and non-standard products. The design is made entirely of stainless steel. Equipped with removable trays for waste disposal. Easy access to all parts of the mechanism for sanitization is provided.

Application: the machine can be used autonomously, as well as be integrated into technological lines for processing vegetables, for inspection and rejection of the product.

Operating principle ;

The product (for example, peeled potatoes) enters the front of the conveyor. Due to the rotation of the rollers, the product turns over and moves in the direction of the tape, which allows the operator to control the quality of cleaning.

| METRIC | TARGET |

|---|---|

| Capacity | up to 3000 kg/h |

| Overall dimensions | 2500×800×1000 mm |

| Installed power | 0,75 kW |

| Power supply | 380/50 V/Hz |

| Total weight | not less than 200 kg |

| Case material | stainless steel |

RUS

RUS