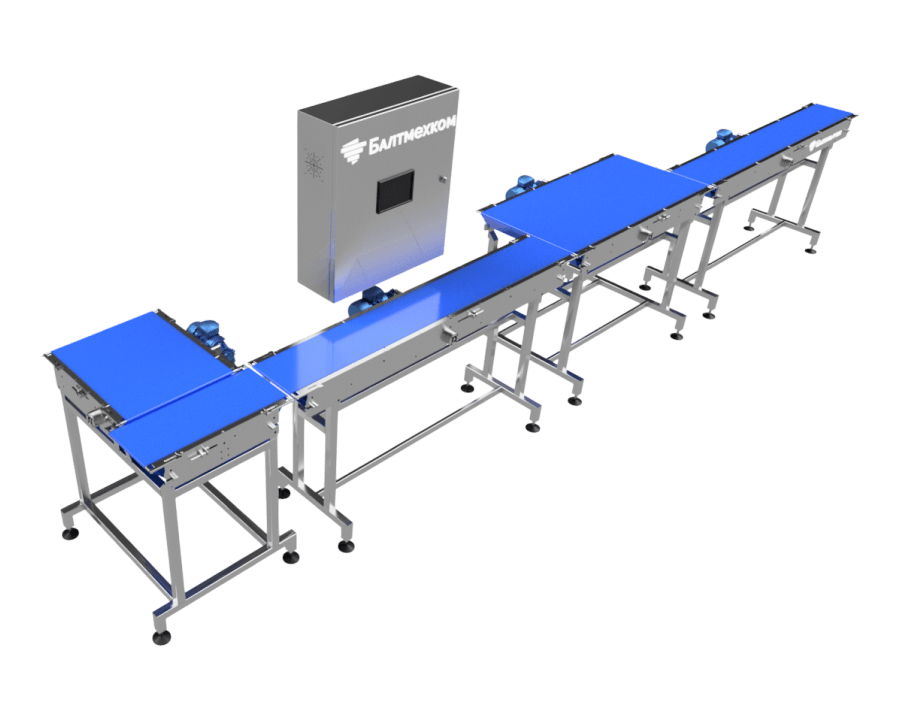

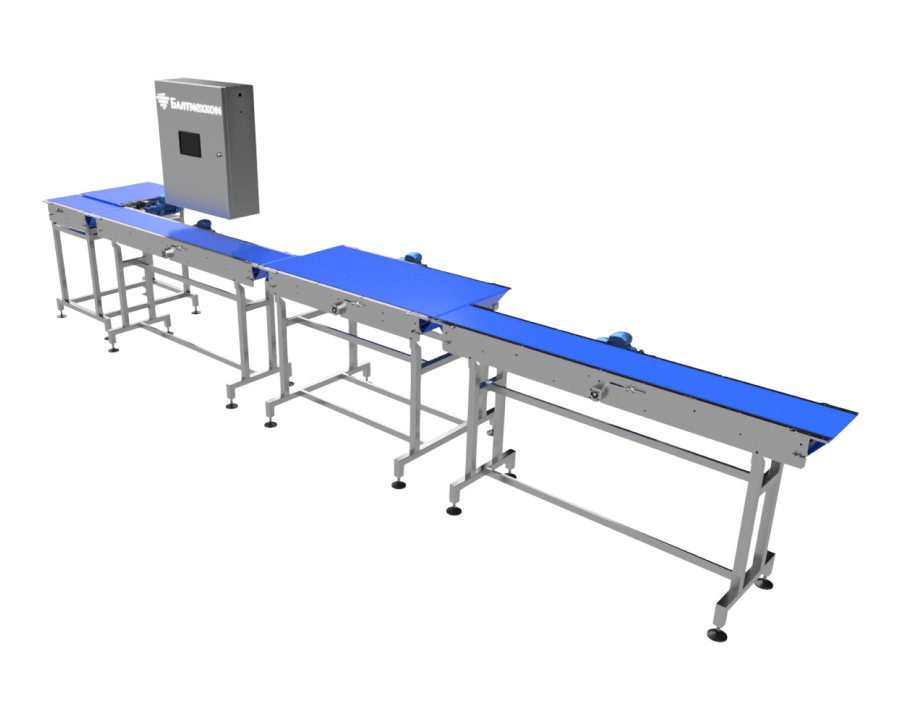

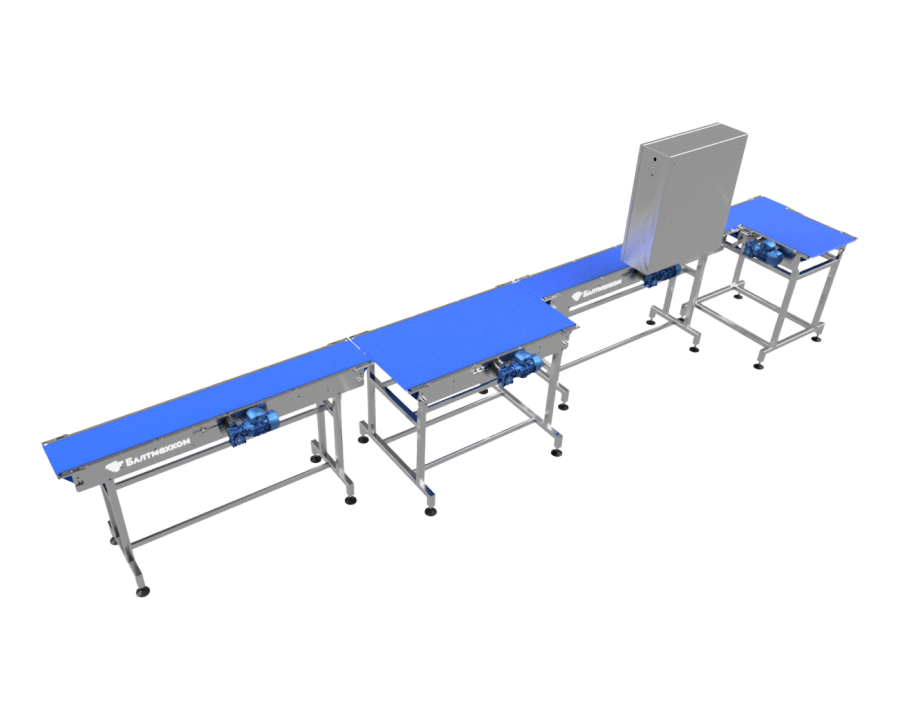

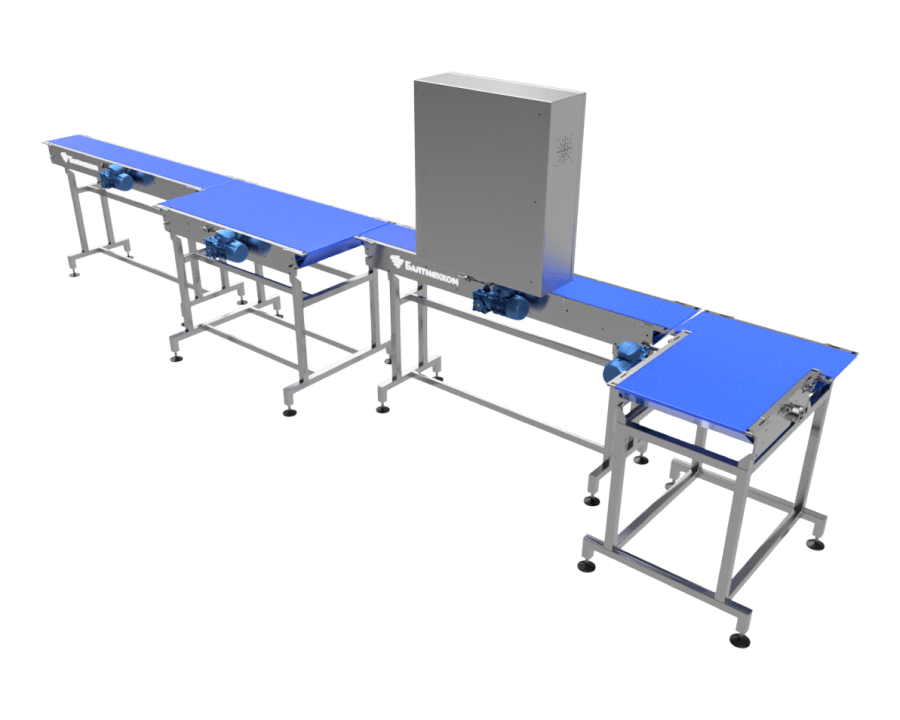

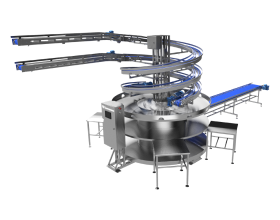

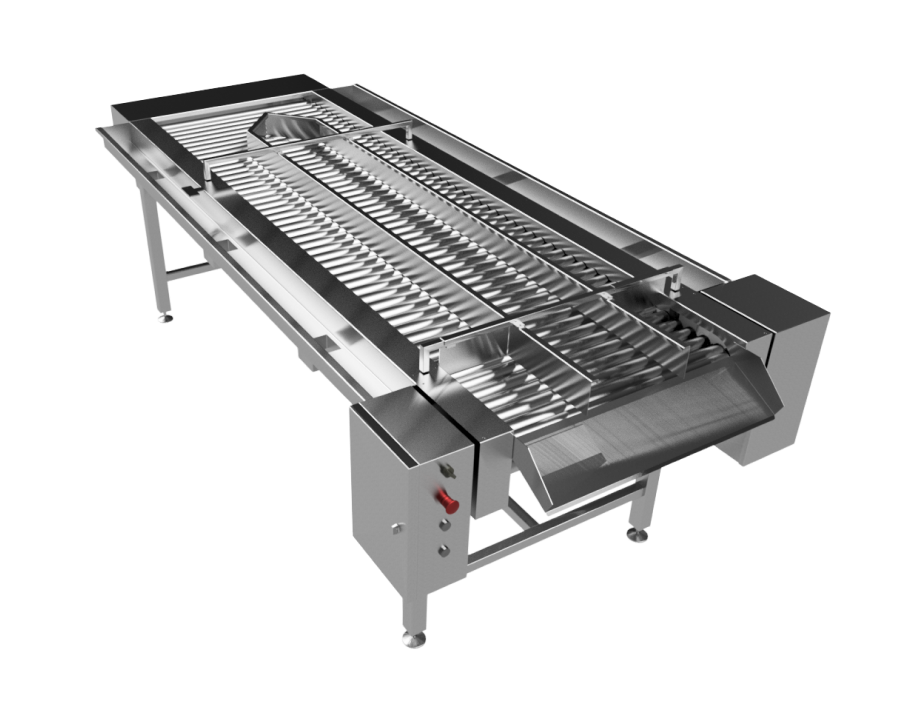

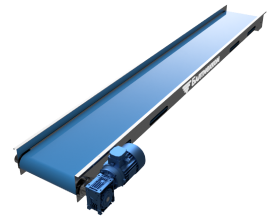

Conveyor line for orientation of chocolate bar

Conveyor line for orientation of chocolate bar

At the exit of the molding machine, a small bar, located in three rows of five pieces each, with a productivity of 12 molds per minute, goes to the booster conveyor to form an interval between the rows. Then, when each row arrives (the object presence sensor is triggered), the discharge conveyor, which is in the transverse direction, is turned on, and the bar is sent to the feeding conveyor in the packaging machine. Due to the higher speed on the feeding conveyor, the bar is positioned with a larger interval than on the discharge conveyor in one row. Next, the bar located in the longitudinal direction of the movement of the tape is oriented by means of a side stop in the transverse direction required for the packaging machine. In the line, a product flow separation pipeline (bypass) is provided for transferring the flow to the second packaging machine.

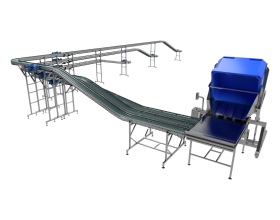

A large bar, located in one row of 5 pieces, when a row arrives at the discharge conveyor (the object presence sensor is activated and the discharge conveyor is turned on) is sent to the feeding conveyor and into the packaging machine already in the position required for packaging.

The line can operate in three basic modes.

1. Screening — the acceleration and discharge (in reverse mode) conveyor are working.

2. Transport and orientation of small bars.

3. Transport and orientation of large bars.

Control panel with controller and LCD display. Drive conveyors — stepper motors with control units.

At the exit of the molding machine, a small bar, located in three rows of five pieces each, with a productivity of 12 molds per minute, goes to the booster conveyor to form an interval between the rows. Then, when each row arrives (the object presence sensor is triggered), the discharge conveyor, which is in the transverse direction, is turned on, and the bar is sent to the feeding conveyor in the packaging machine. Due to the higher speed on the feeding conveyor, the bar is positioned with a larger interval than on the discharge conveyor in one row. Next, the bar located in the longitudinal direction of the movement of the tape is oriented by means of a side stop in the transverse direction required for the packaging machine. In the line, a product flow separation pipeline (bypass) is provided for transferring the flow to the second packaging machine.

A large bar, located in one row of 5 pieces, when a row arrives at the discharge conveyor (the object presence sensor is activated and the discharge conveyor is turned on) is sent to the feeding conveyor and into the packaging machine already in the position required for packaging.

The line can operate in three basic modes.

1. Screening — the acceleration and discharge (in reverse mode) conveyor are working.

2. Transport and orientation of small bars.

3. Transport and orientation of large bars.

Control panel with controller and LCD display. Drive conveyors — stepper motors with control units.

RUS

RUS