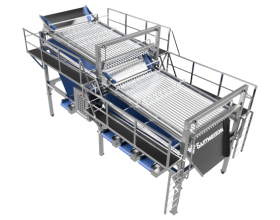

Fish grading line

Fish grading line

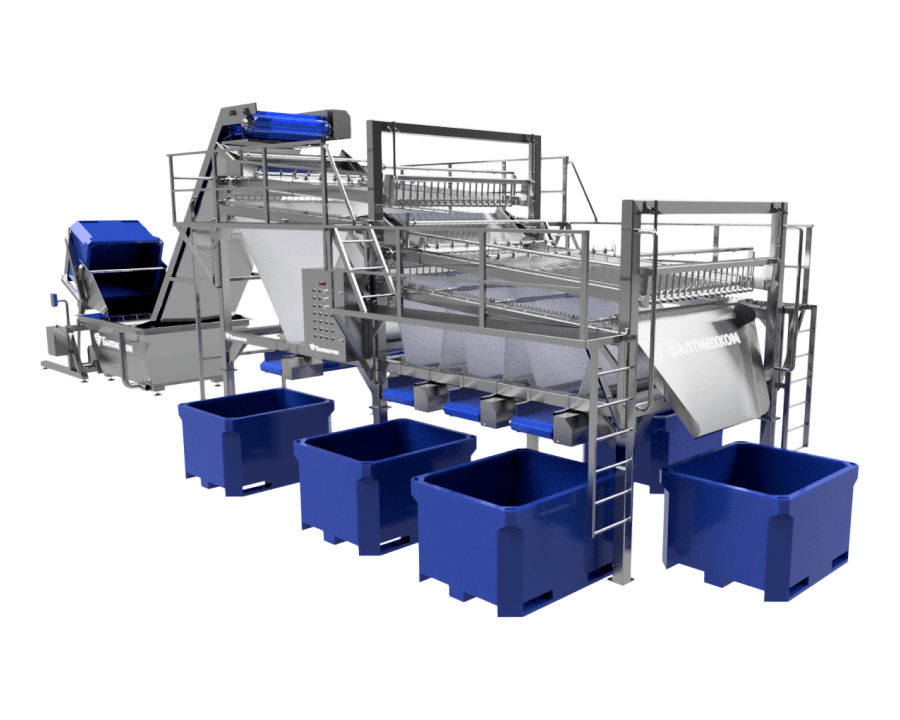

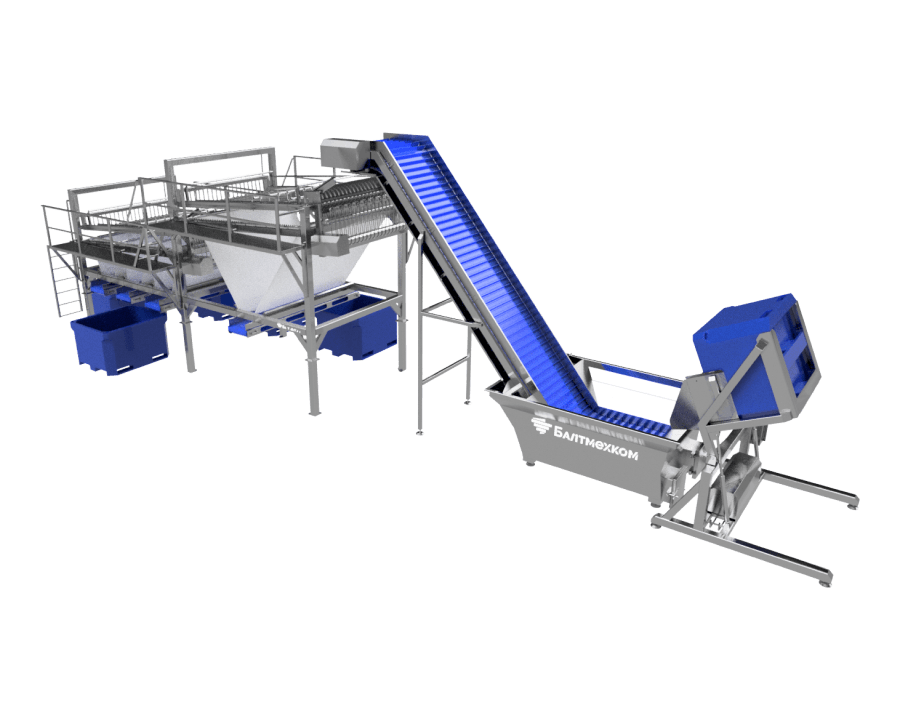

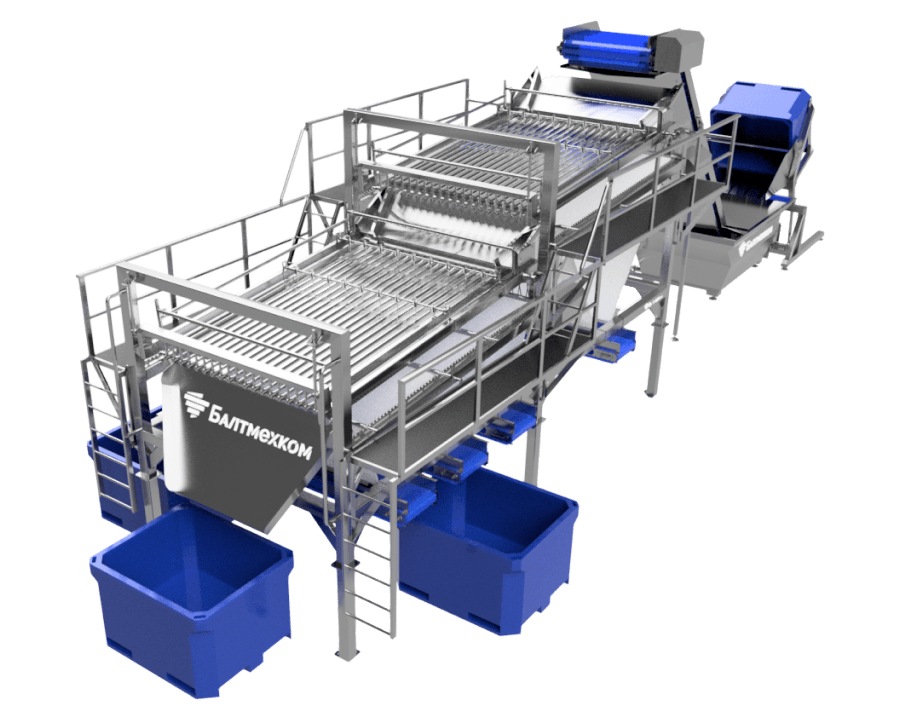

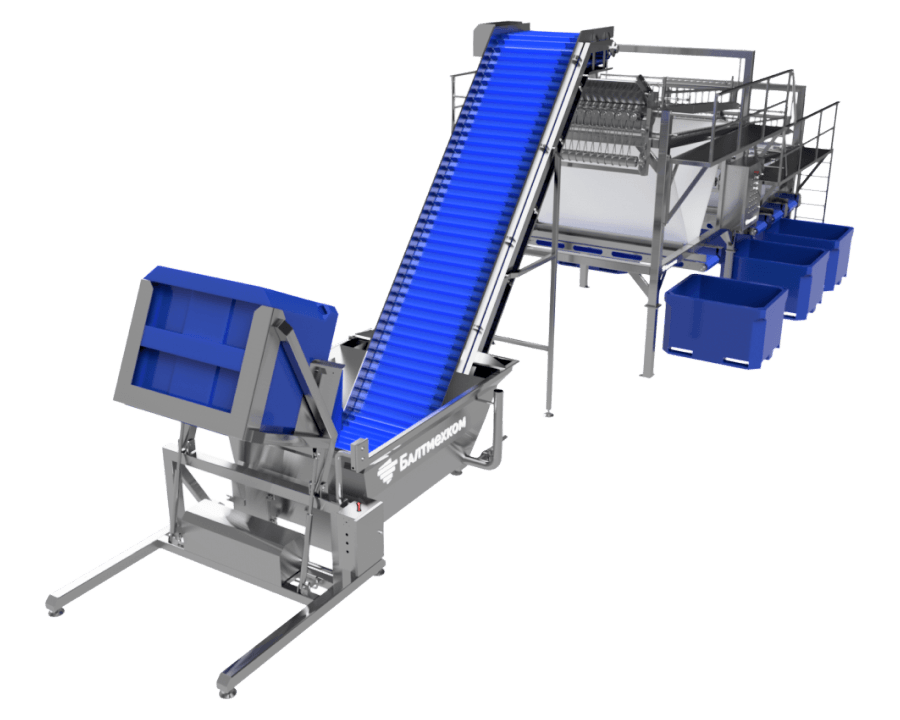

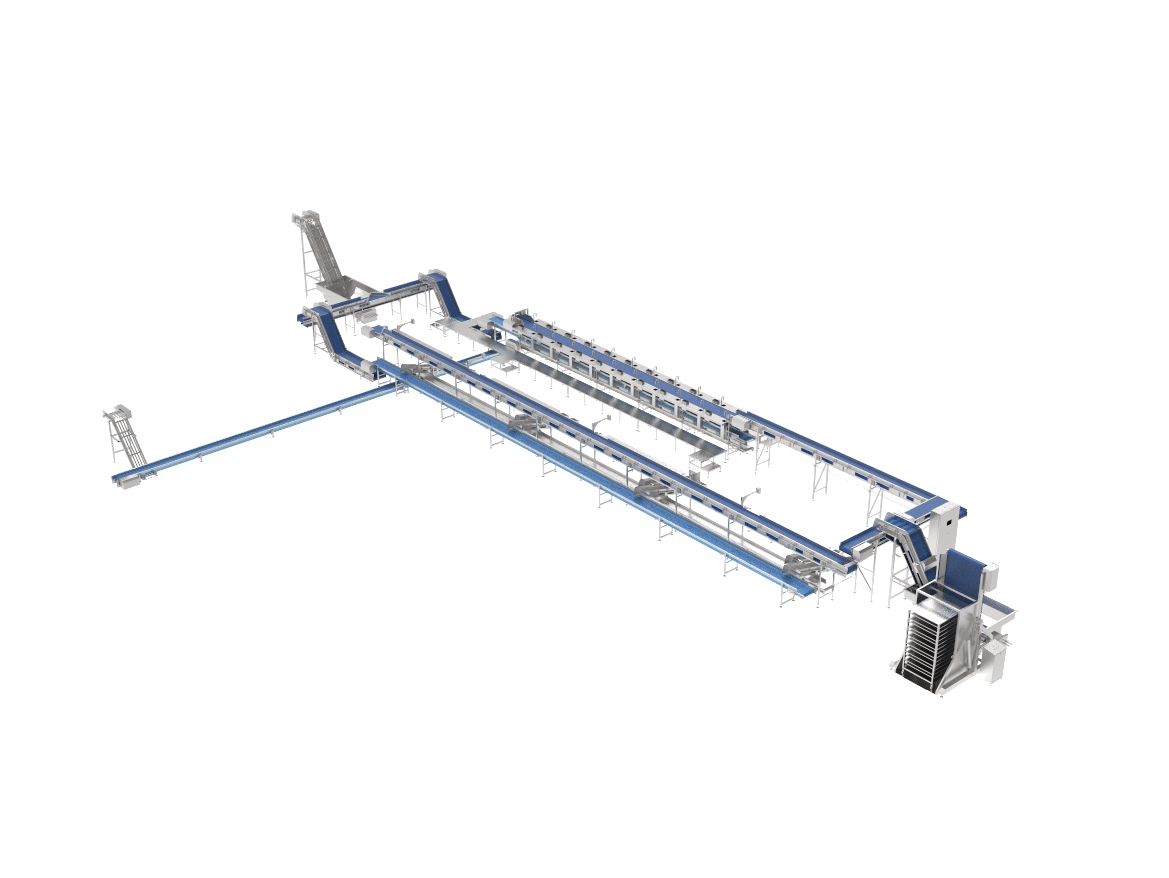

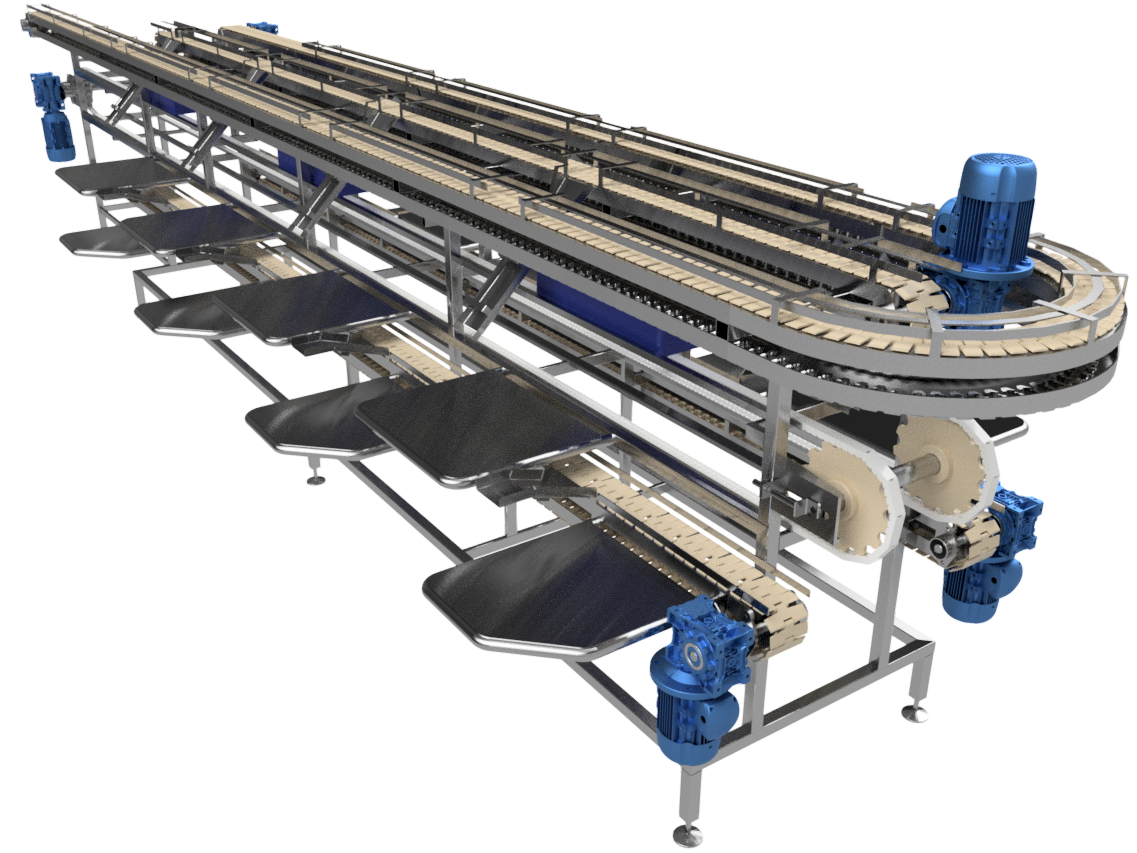

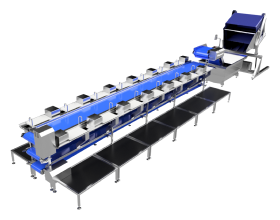

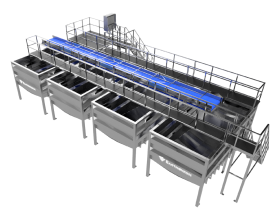

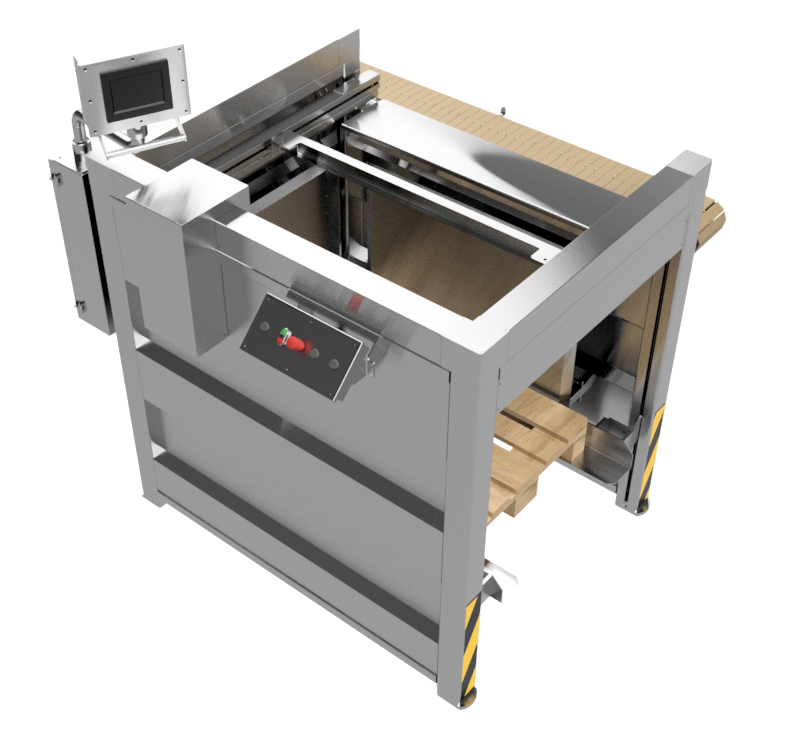

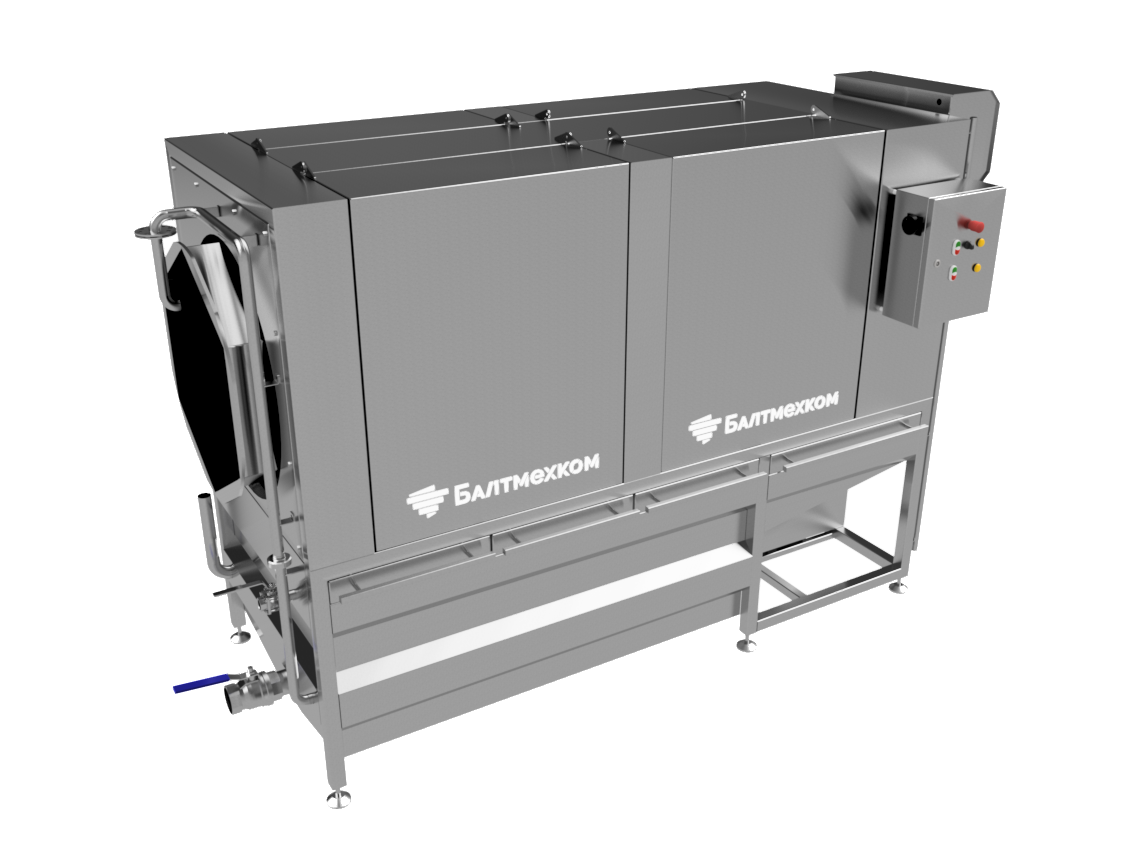

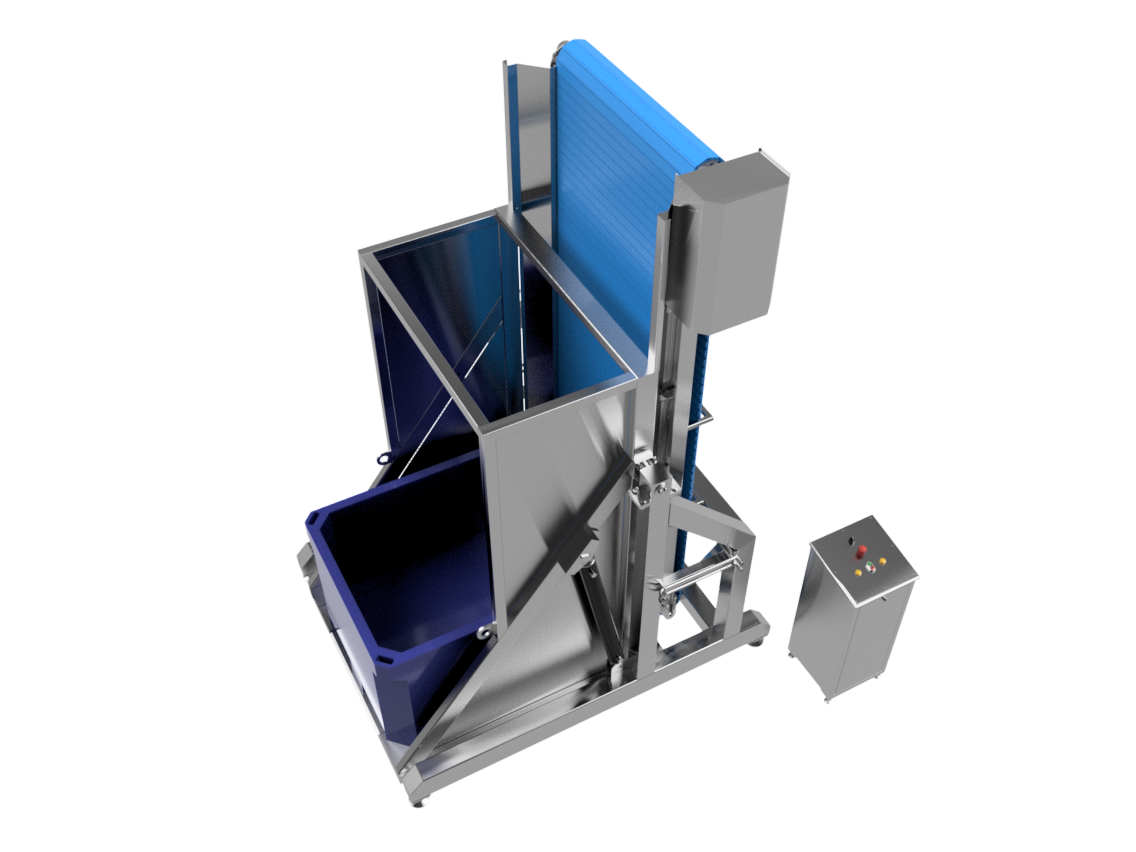

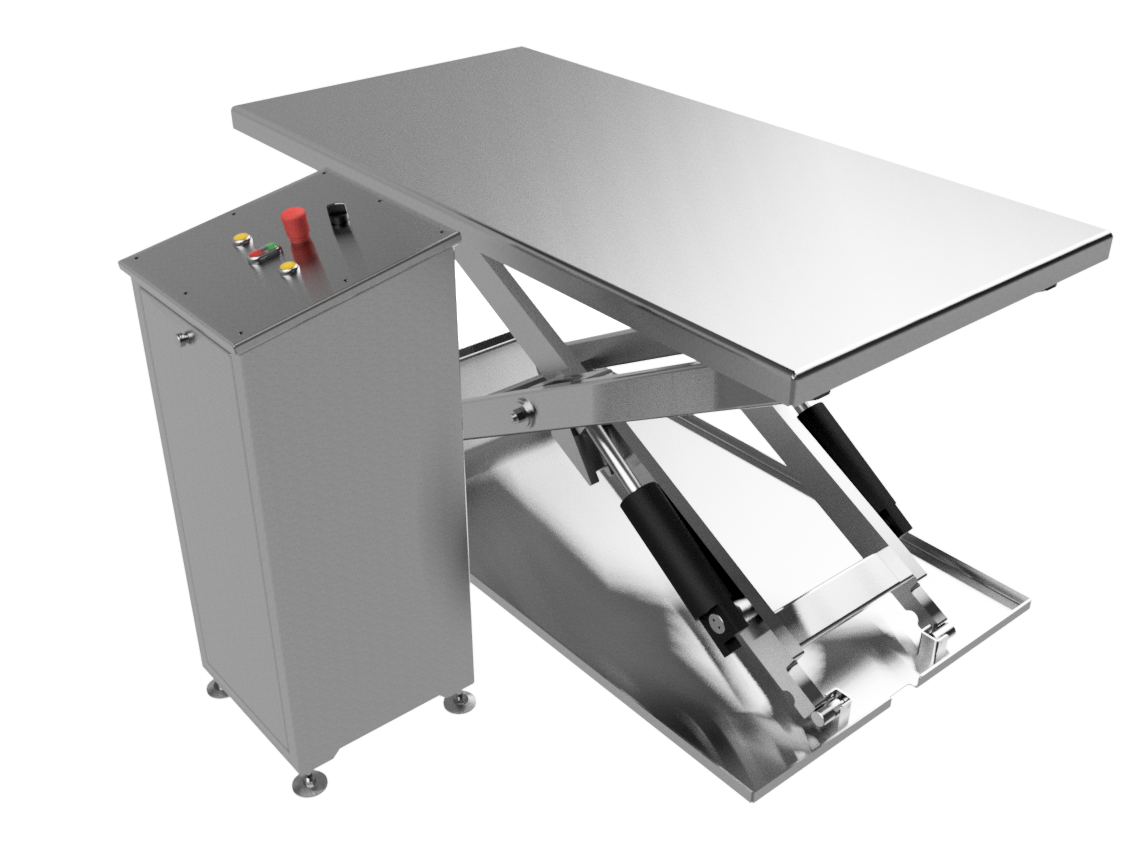

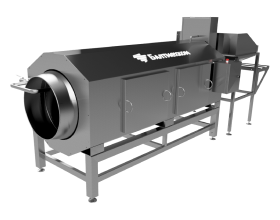

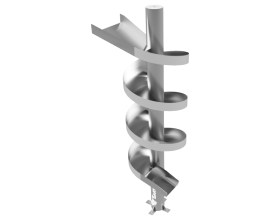

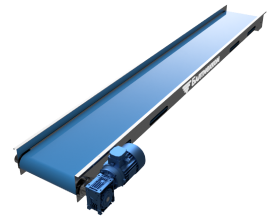

The line consists of a box tipper, a hopper-elevator, a fish grading machine with service platforms, discharge conveyors, storage tanks.

The fish in containers enters in the zone of acceptance. The container with fish rolls into the tipper and turns over into a washing-elevator bathtub that is pre-filled with water. The fish is continuously mixed and washed due to the movement of the conveyor, the water is constantly updated due to overflow. Next, the fish on the elevator scraper conveyor enters the sorting. When feeding fish in bulk, it tends to get into a position along the axis of the sorting rollers. Small fish, depending on the selected gap will fall into the slots and fall on one of the discharge conveyors, larger move on the way out and fall on another conveyor. The separation can be made into several fractions. It depends on the selected clearances and the number of discharge trays. The conveyor sorted fish enters storage tanks and then for further processing or freezing.

The line consists of a box tipper, a hopper-elevator, a fish grading machine with service platforms, discharge conveyors, storage tanks.

The fish in containers enters in the zone of acceptance. The container with fish rolls into the tipper and turns over into a washing-elevator bathtub that is pre-filled with water. The fish is continuously mixed and washed due to the movement of the conveyor, the water is constantly updated due to overflow. Next, the fish on the elevator scraper conveyor enters the sorting. When feeding fish in bulk, it tends to get into a position along the axis of the sorting rollers. Small fish, depending on the selected gap will fall into the slots and fall on one of the discharge conveyors, larger move on the way out and fall on another conveyor. The separation can be made into several fractions. It depends on the selected clearances and the number of discharge trays. The conveyor sorted fish enters storage tanks and then for further processing or freezing.

RUS

RUS