Production area for processing fish

Production area for processing fish

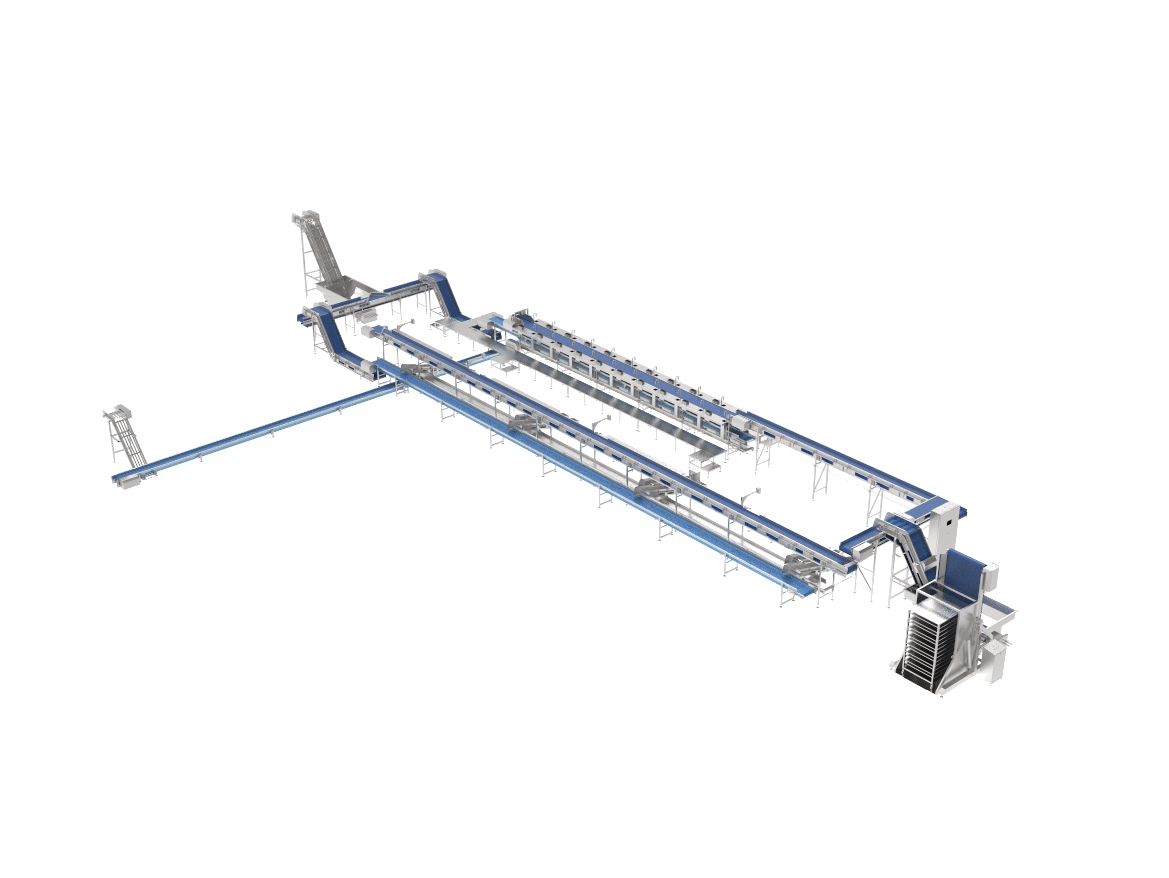

The production area includes a set of equipment designed for processing fish after defrosting into carcasses or fillets on two types of cutting lines: a manual cutting line and a nobbing machine line.

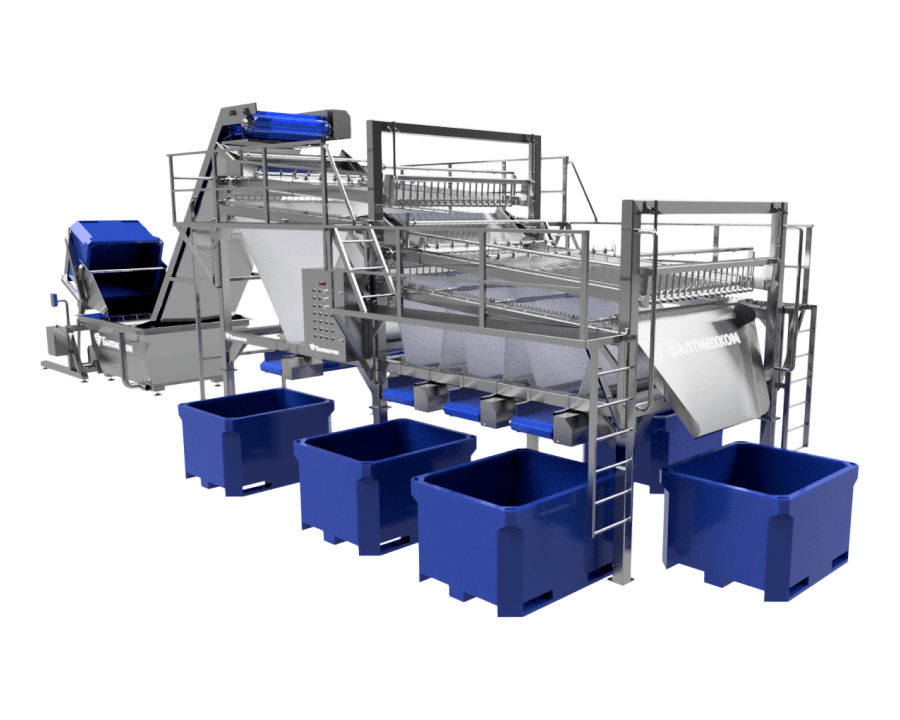

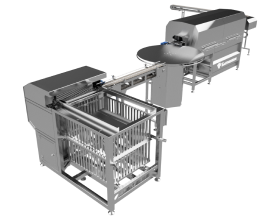

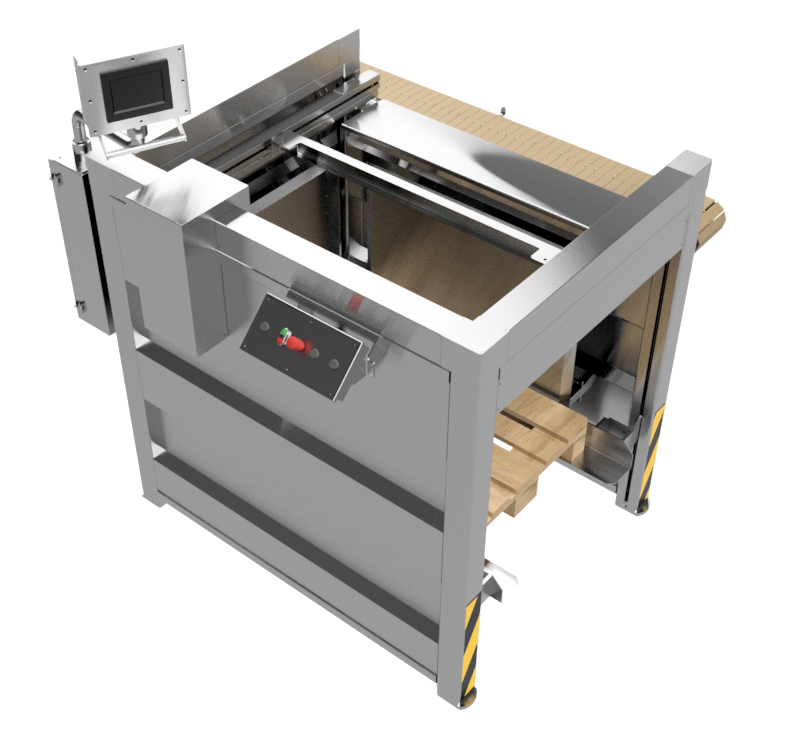

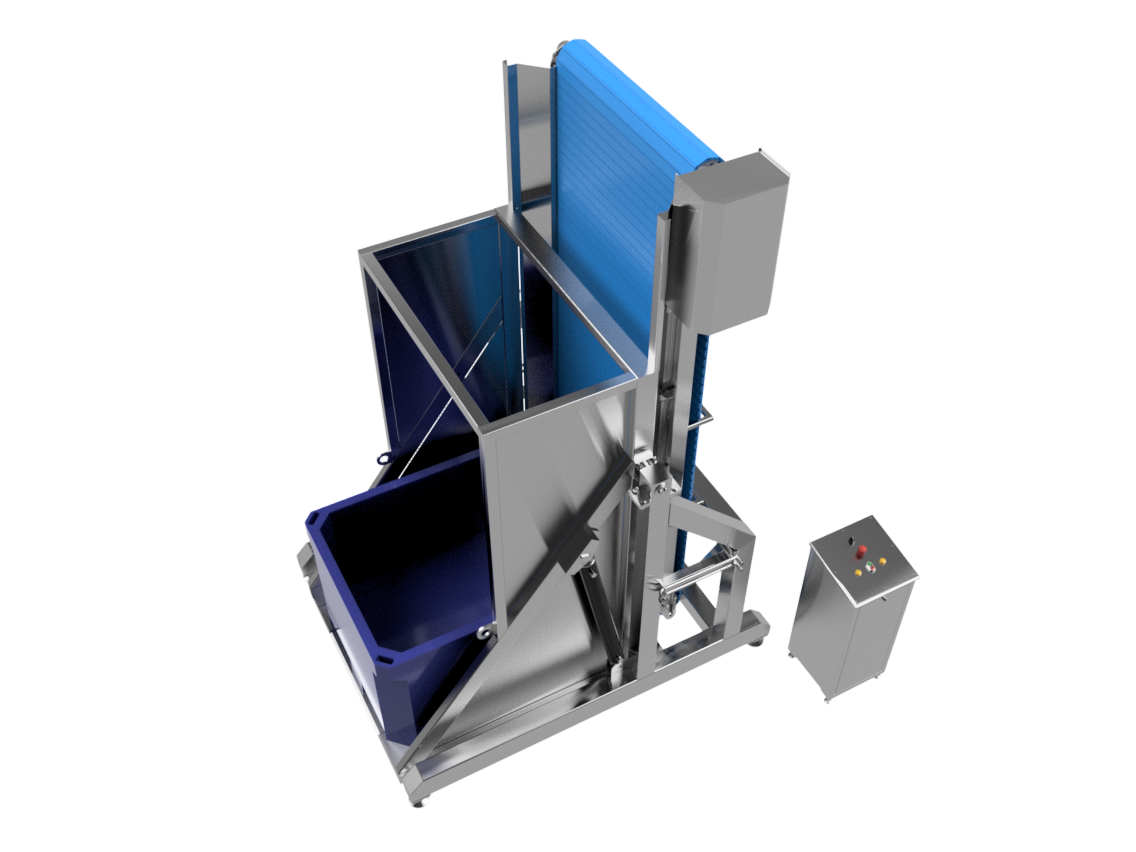

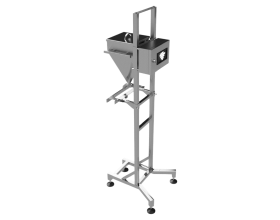

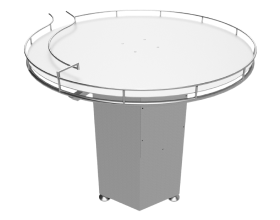

Defrosted fish is fed into the cage tipper, then along the conveyor into the hopper, where after rinsing it is raised to the required height and sent to one of the lines by a reversible conveyor.

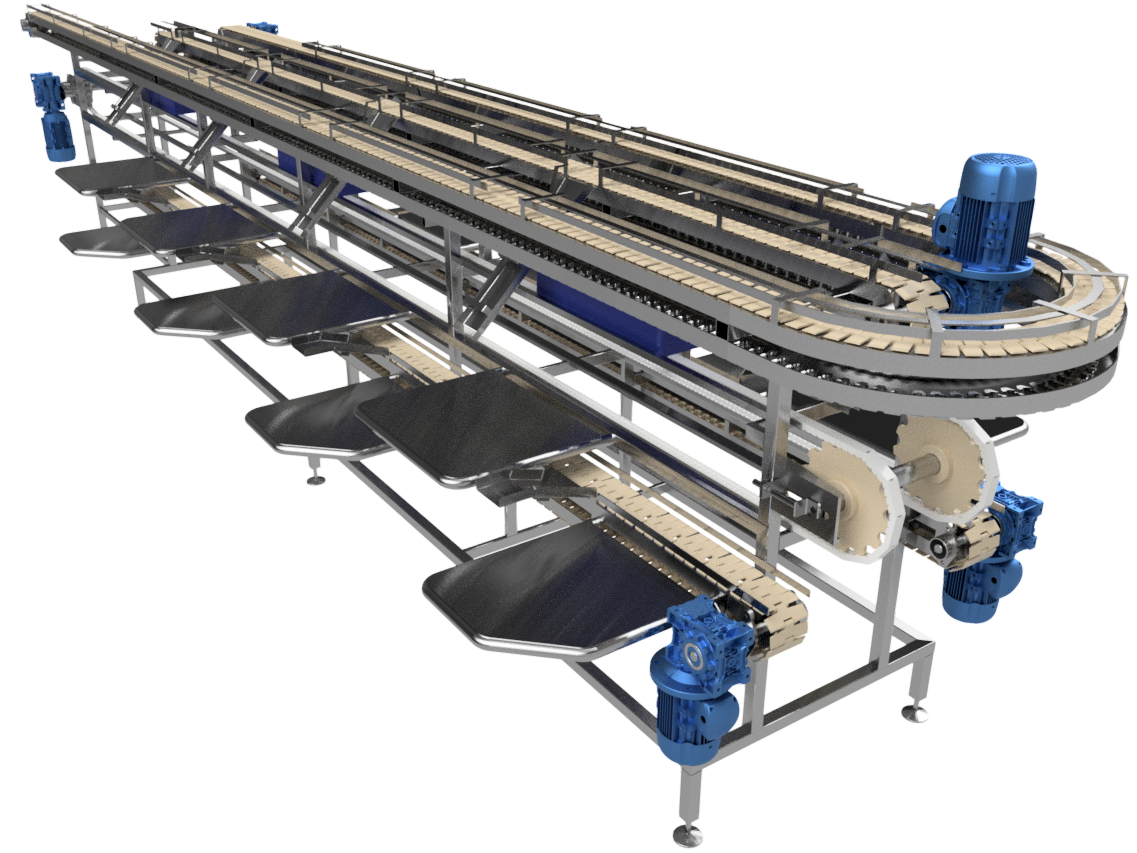

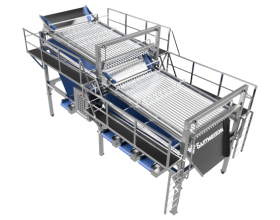

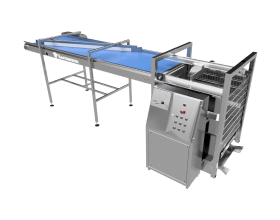

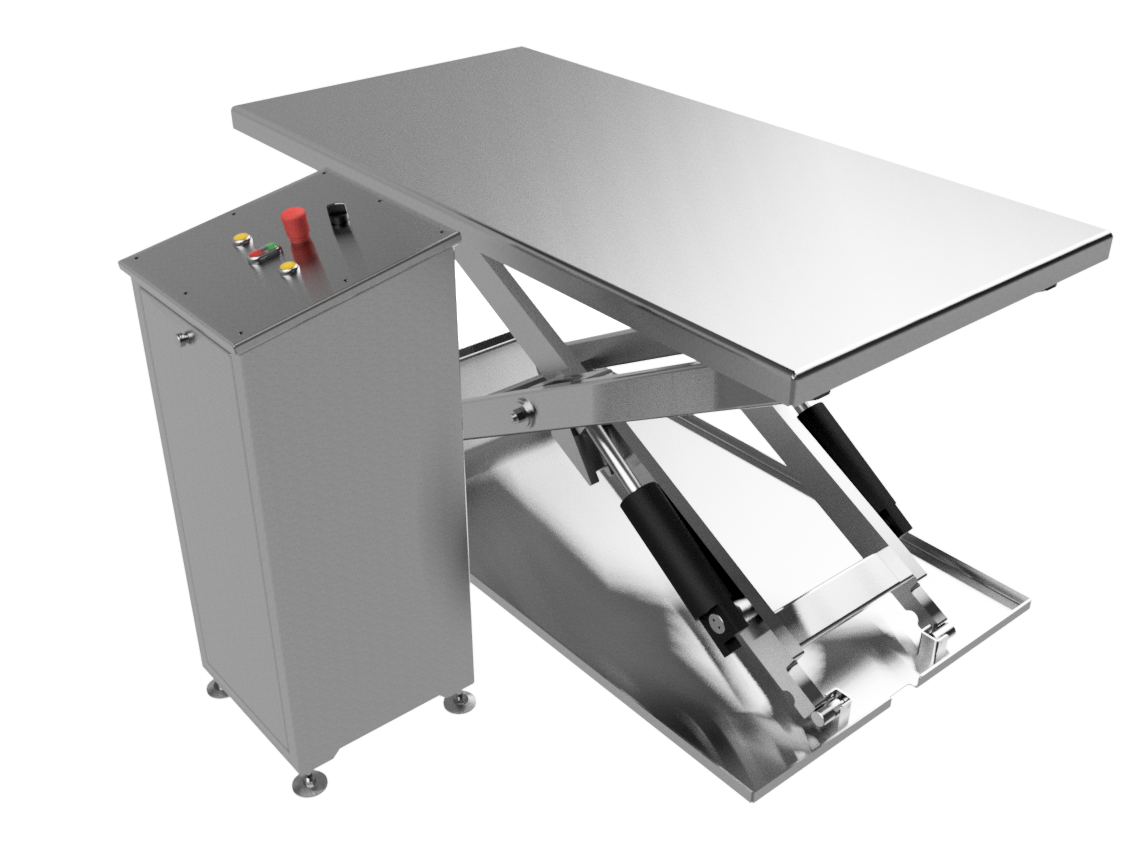

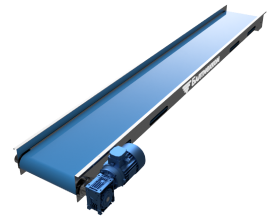

Line for manual cutting of fish into fillets and carcasses. Designed for 20 workstations, consists of a system of conveyors and work surfaces that ensure continuous supply and removal of cut fish, as well as waste removal, which allows achieving maximum productivity. Water is supplied to each workstation.

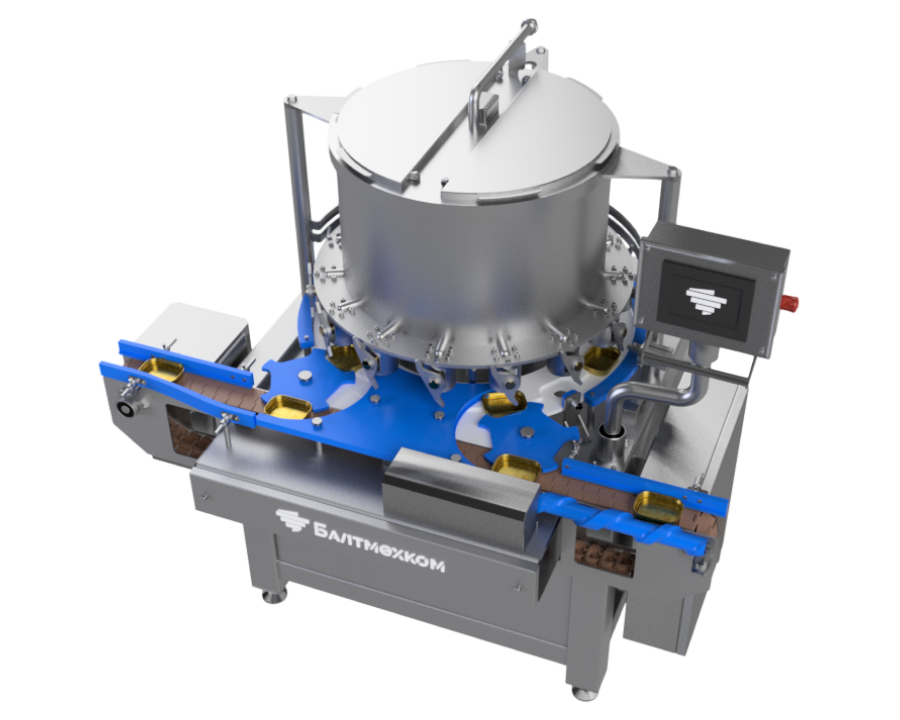

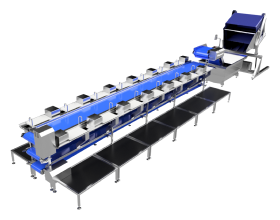

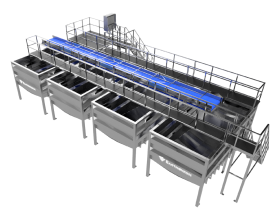

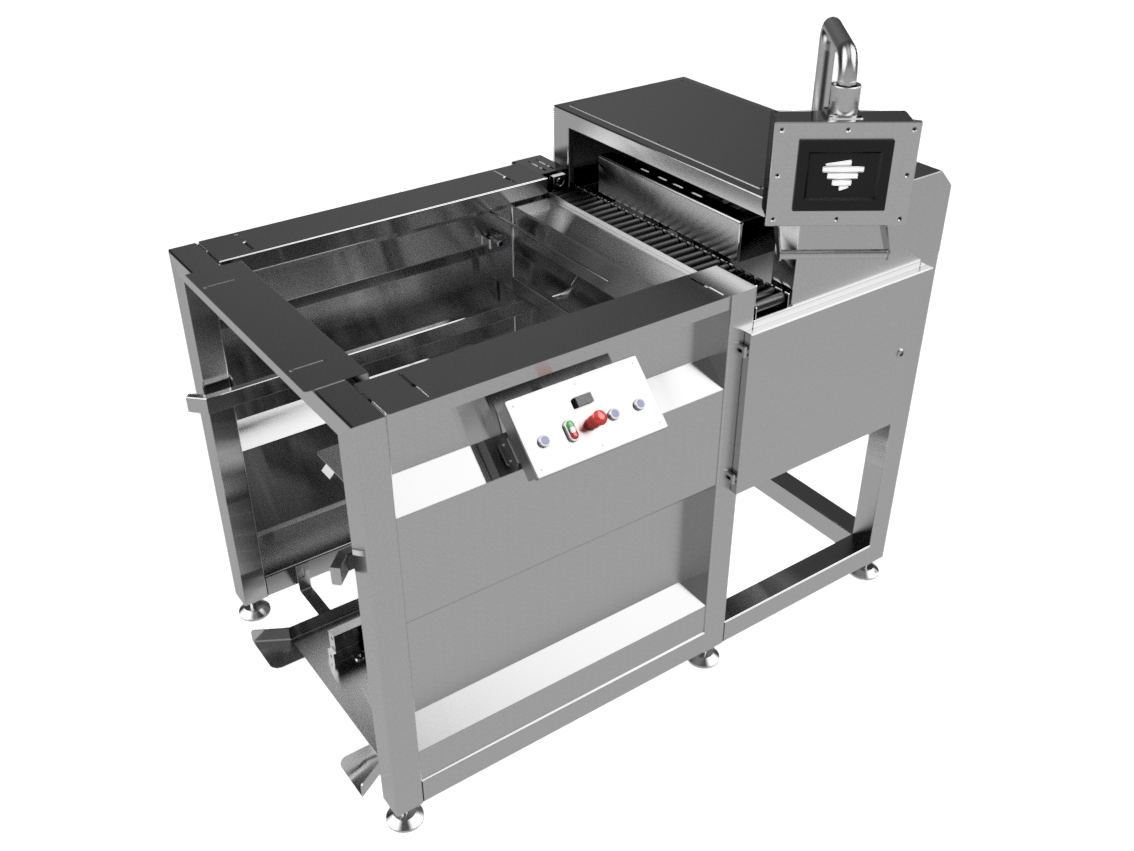

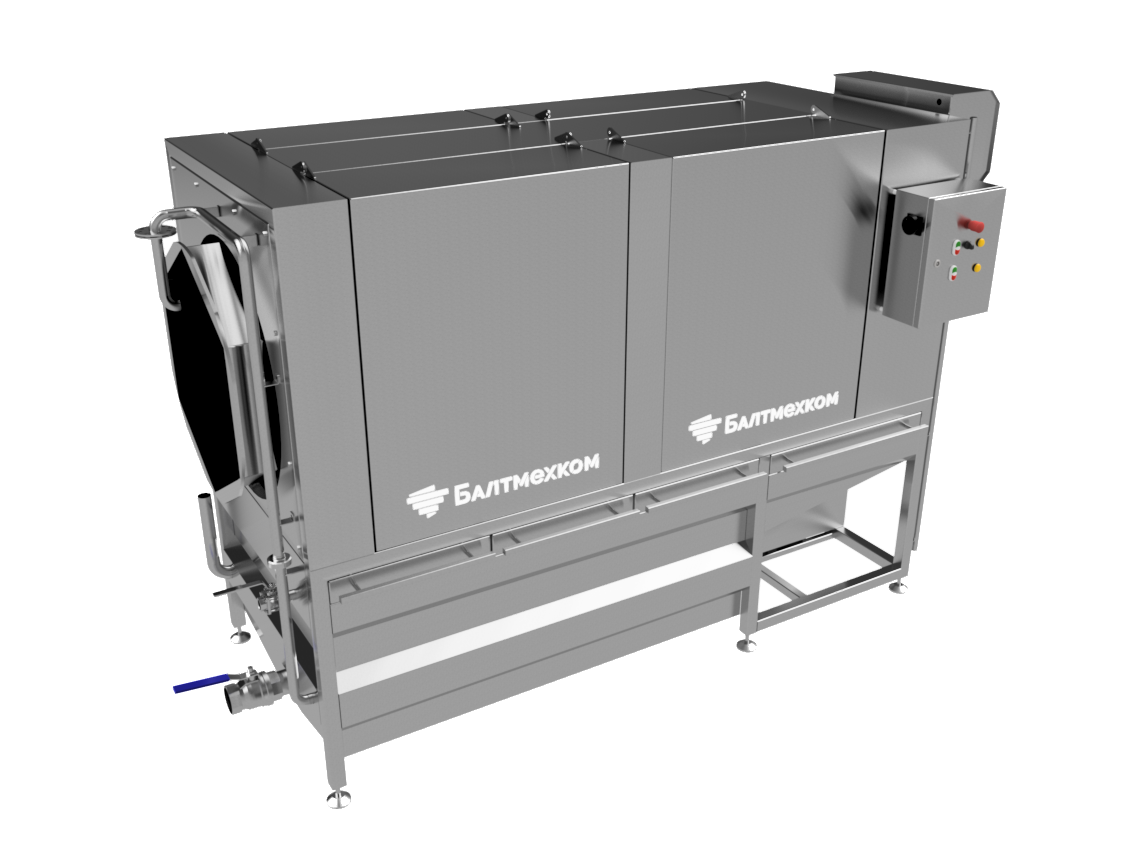

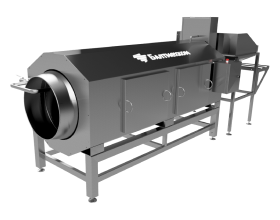

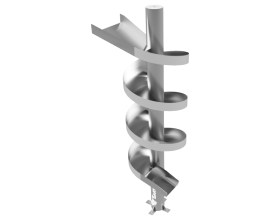

The mechanical cutting line is designed for 8 workstations, consists of four nobbing machines and a system of conveyors and work surfaces that ensure continuous supply and removal of cut fish, as well as waste removal. The cut fish is lifted by Z-shaped conveyors onto a reversible conveyor and fed into the washing elevator and then into the stuffing machines of the packaging section. The waste is discharged by the conveyor system into storage tanks for further processing.

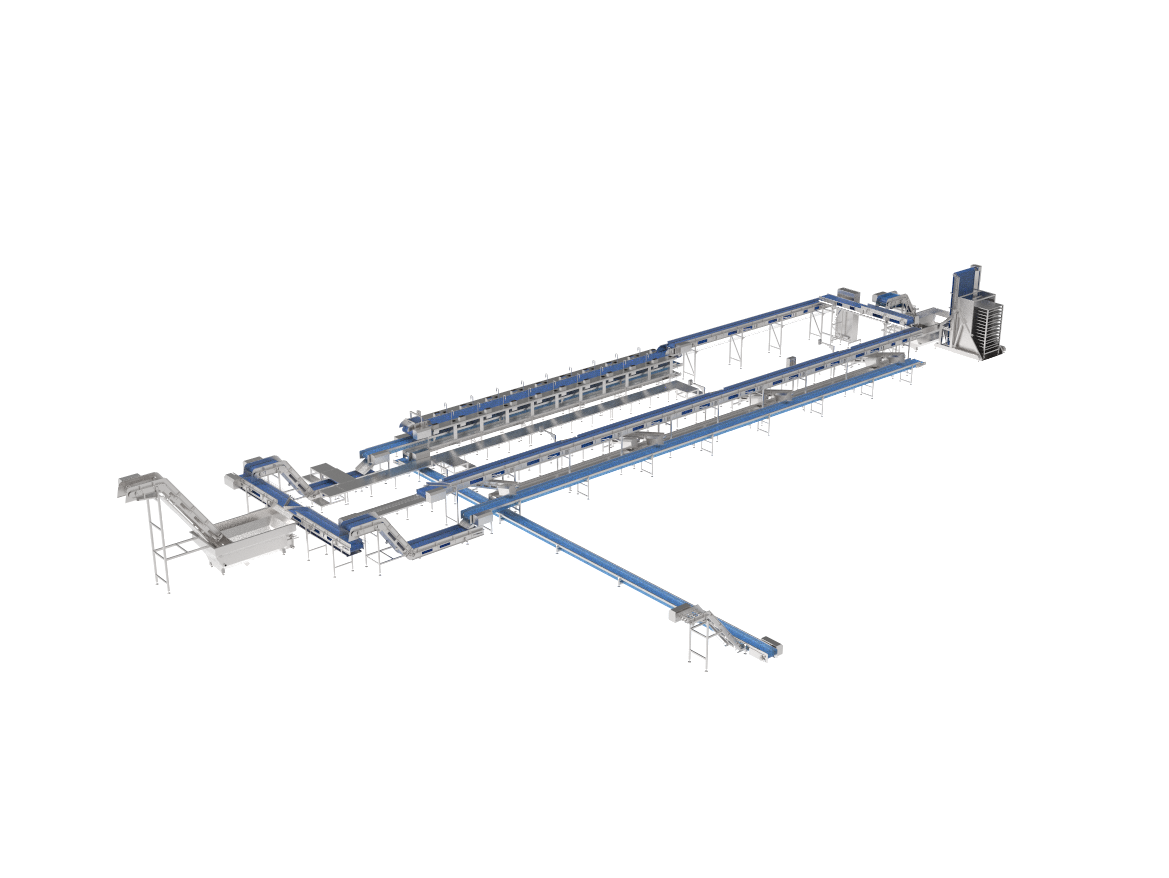

The production area includes a set of equipment designed for processing fish after defrosting into carcasses or fillets on two types of cutting lines: a manual cutting line and a nobbing machine line.

Defrosted fish is fed into the cage tipper, then along the conveyor into the hopper, where after rinsing it is raised to the required height and sent to one of the lines by a reversible conveyor.

Line for manual cutting of fish into fillets and carcasses. Designed for 20 workstations, consists of a system of conveyors and work surfaces that ensure continuous supply and removal of cut fish, as well as waste removal, which allows achieving maximum productivity. Water is supplied to each workstation.

The mechanical cutting line is designed for 8 workstations, consists of four nobbing machines and a system of conveyors and work surfaces that ensure continuous supply and removal of cut fish, as well as waste removal. The cut fish is lifted by Z-shaped conveyors onto a reversible conveyor and fed into the washing elevator and then into the stuffing machines of the packaging section. The waste is discharged by the conveyor system into storage tanks for further processing.

RUS

RUS