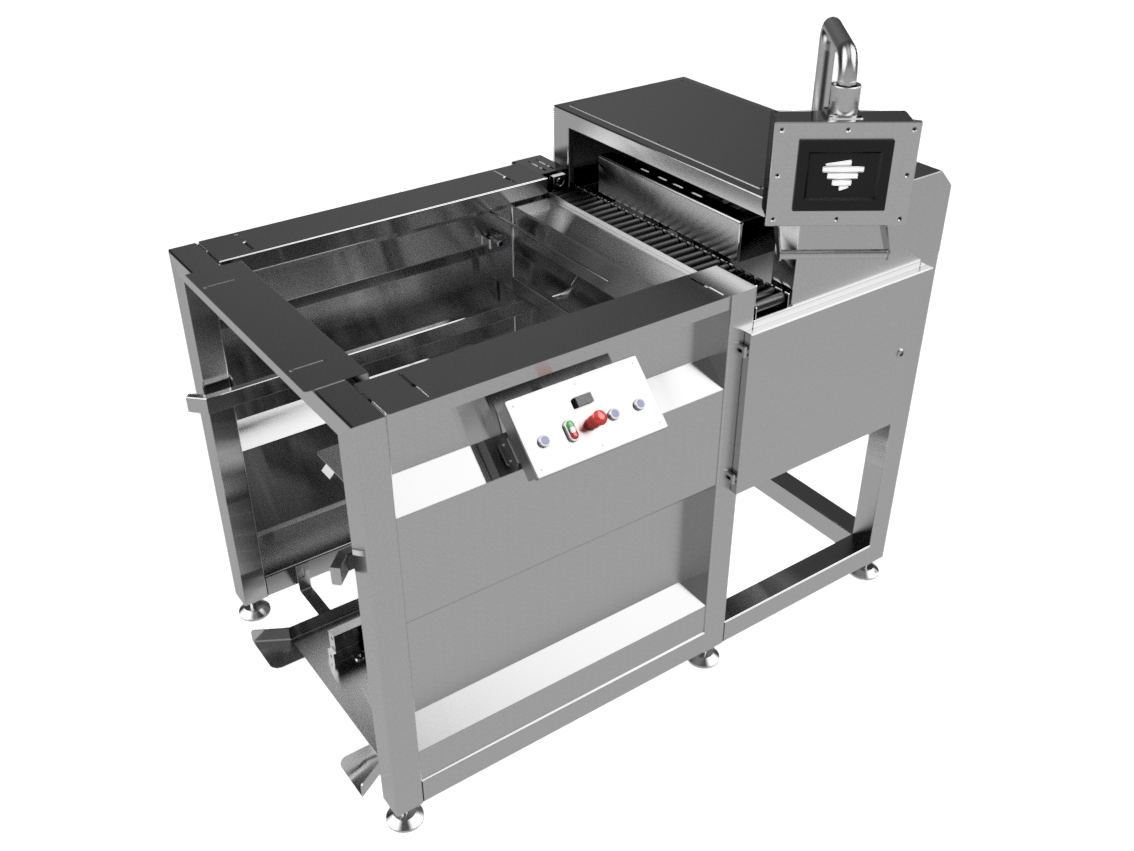

Can Washer

Can Washer

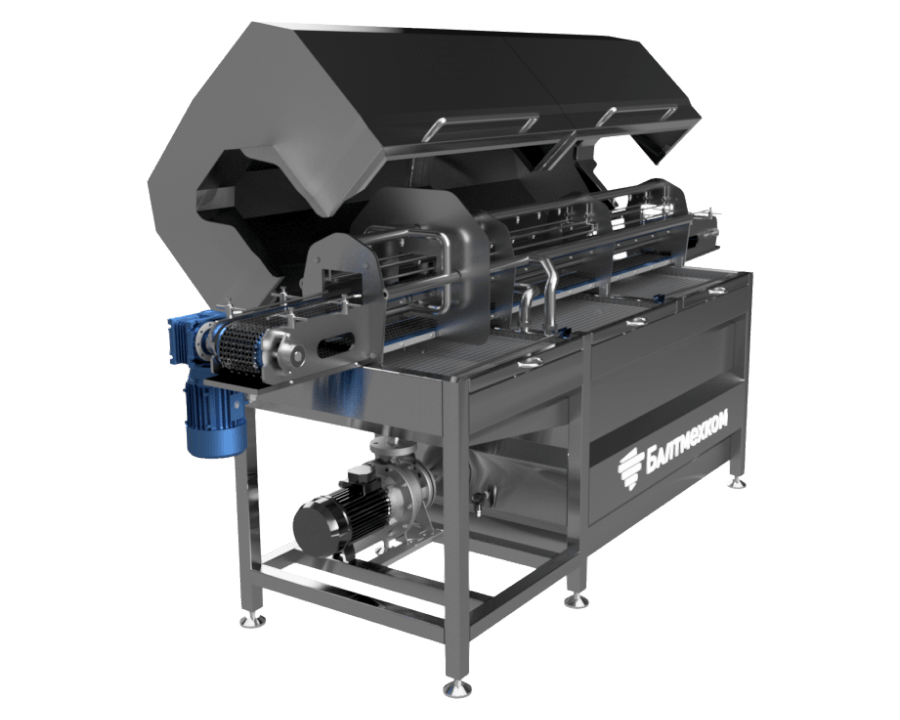

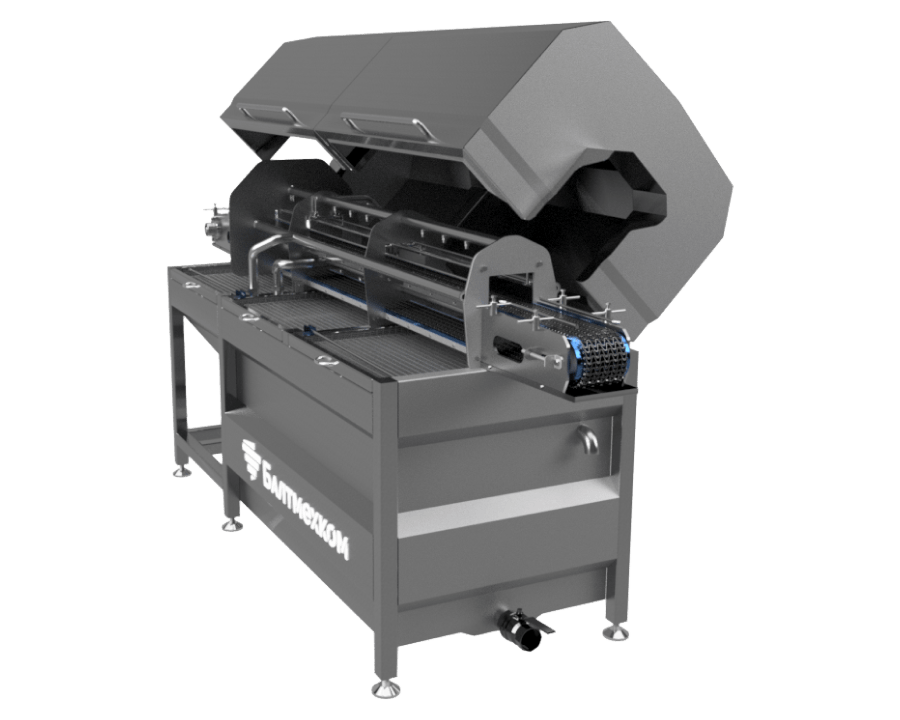

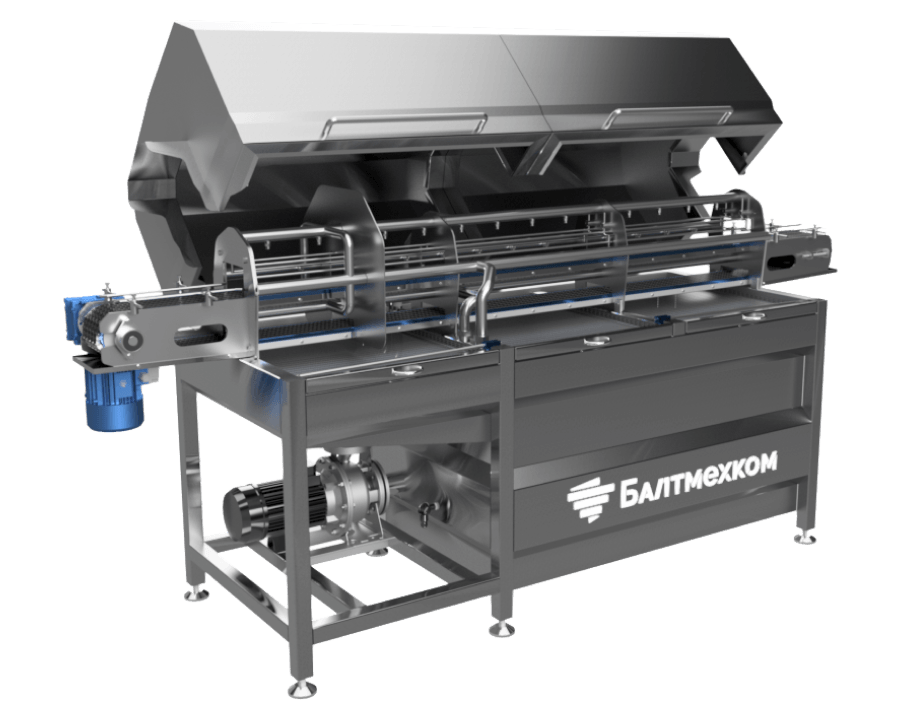

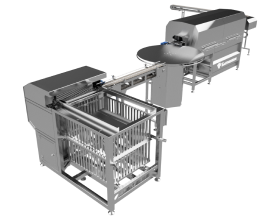

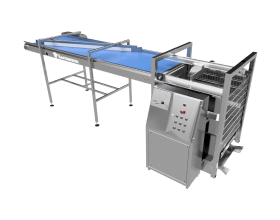

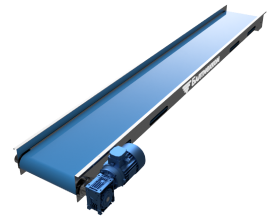

The linear type machine is designed for washing filled cylindrical and shaped cans. The maximum diameter of the can is D = 120mm, the maximum height is 90mm. Adjusting the line to the desired can size is done by changing the position of the guides along the entire length of the conveyor. Washing is carried out by a jet method using nozzles. Cans come on a horizontal mesh conveyor in the washing unit. In the first part of the washing tunnel, the can is washed with a washing solution that circulates in a closed loop (the recommended solution temperature max. 60 * C is maintained automatically by the supply of live steam). In the second part, it is rinsed with running water (to reduce steam consumption, the recommended t / max is 40-50 * C). There is no heating of water in the supply and rinsing system. The tank of cleaning unit is filled with cleaning solution. In the normal mode, the bath is replenished by supplying water to the rinsing section, and the level is maintained by the overflow pipe; periodic monitoring of the concentration of the washing solution is necessary. Water drainage from the rinsing area to the sewage system is also provided, in this case the level of the solution in the bath is regulated by a float valve in the supply system. The pressure of the circulation pump required for high-quality washing of cans is regulated by the bypass. The pressure in the supply and rinse system must be at least 0.3 MPa. Retractable strainers are located under the conveyor frame.

The linear type machine is designed for washing filled cylindrical and shaped cans. The maximum diameter of the can is D = 120mm, the maximum height is 90mm. Adjusting the line to the desired can size is done by changing the position of the guides along the entire length of the conveyor. Washing is carried out by a jet method using nozzles. Cans come on a horizontal mesh conveyor in the washing unit. In the first part of the washing tunnel, the can is washed with a washing solution that circulates in a closed loop (the recommended solution temperature max. 60 * C is maintained automatically by the supply of live steam). In the second part, it is rinsed with running water (to reduce steam consumption, the recommended t / max is 40-50 * C). There is no heating of water in the supply and rinsing system. The tank of cleaning unit is filled with cleaning solution. In the normal mode, the bath is replenished by supplying water to the rinsing section, and the level is maintained by the overflow pipe; periodic monitoring of the concentration of the washing solution is necessary. Water drainage from the rinsing area to the sewage system is also provided, in this case the level of the solution in the bath is regulated by a float valve in the supply system. The pressure of the circulation pump required for high-quality washing of cans is regulated by the bypass. The pressure in the supply and rinse system must be at least 0.3 MPa. Retractable strainers are located under the conveyor frame.

| METRIC | TARGET |

|---|---|

| Capacity | 120 cans/min |

| Steam consumption | 60 kg/h |

| Installed power | 3.0 kW |

| Overall dimensions | 2600×1500×800 mm |

RUS

RUS