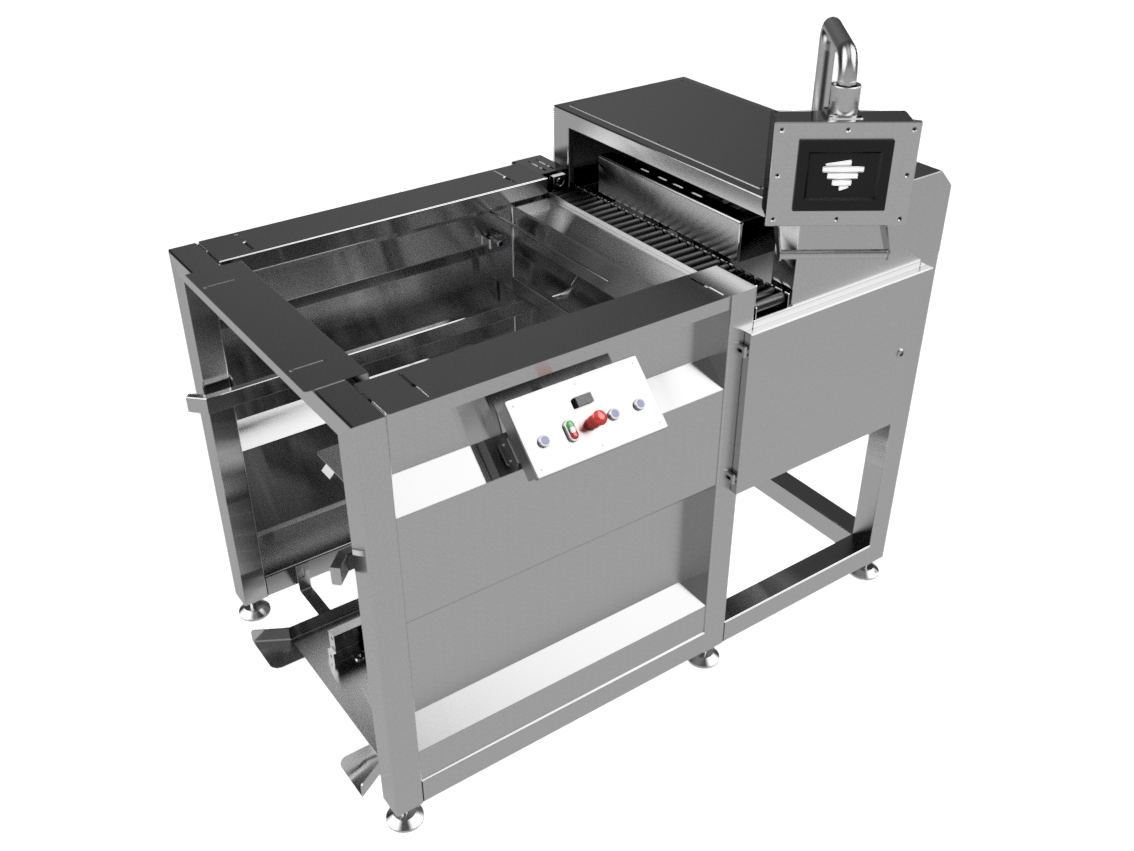

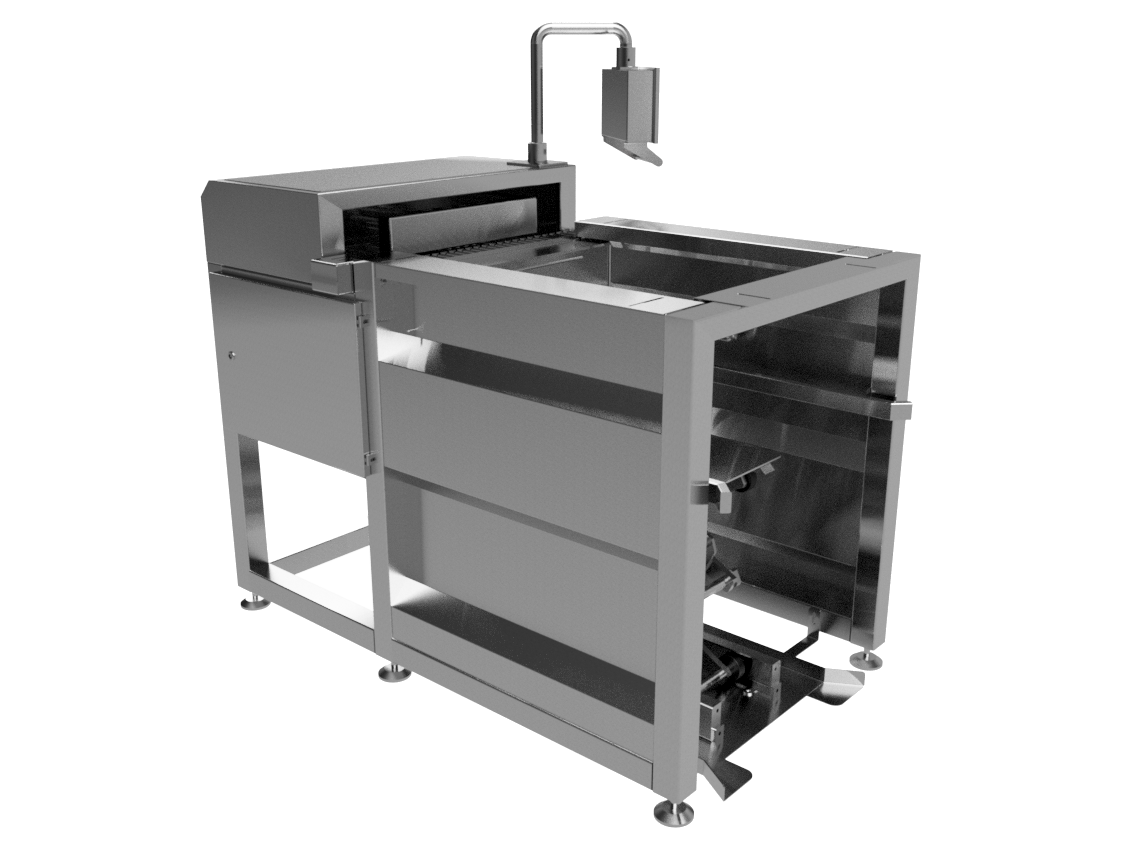

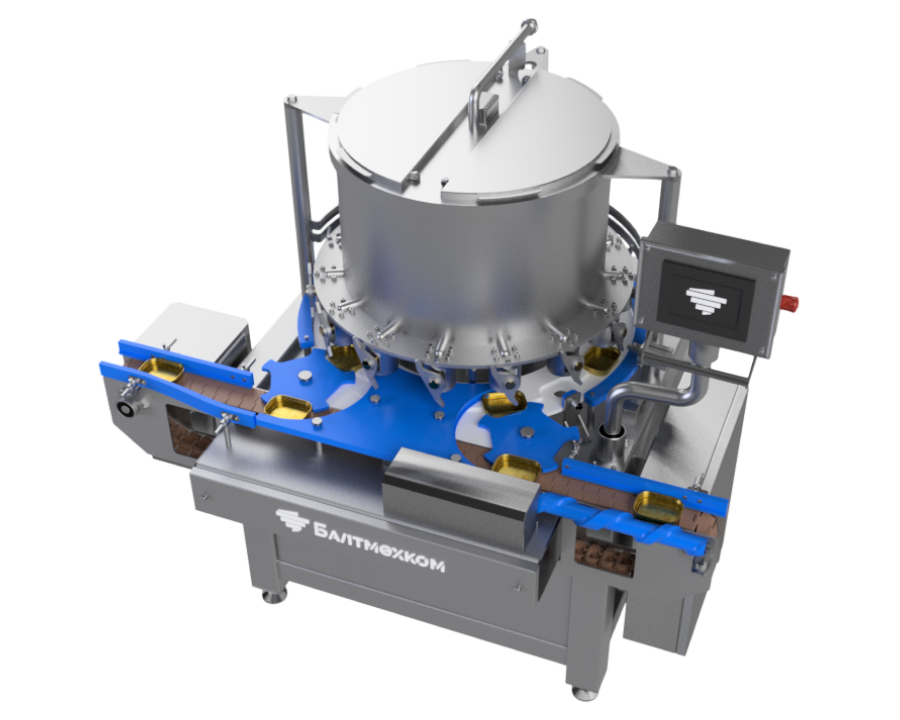

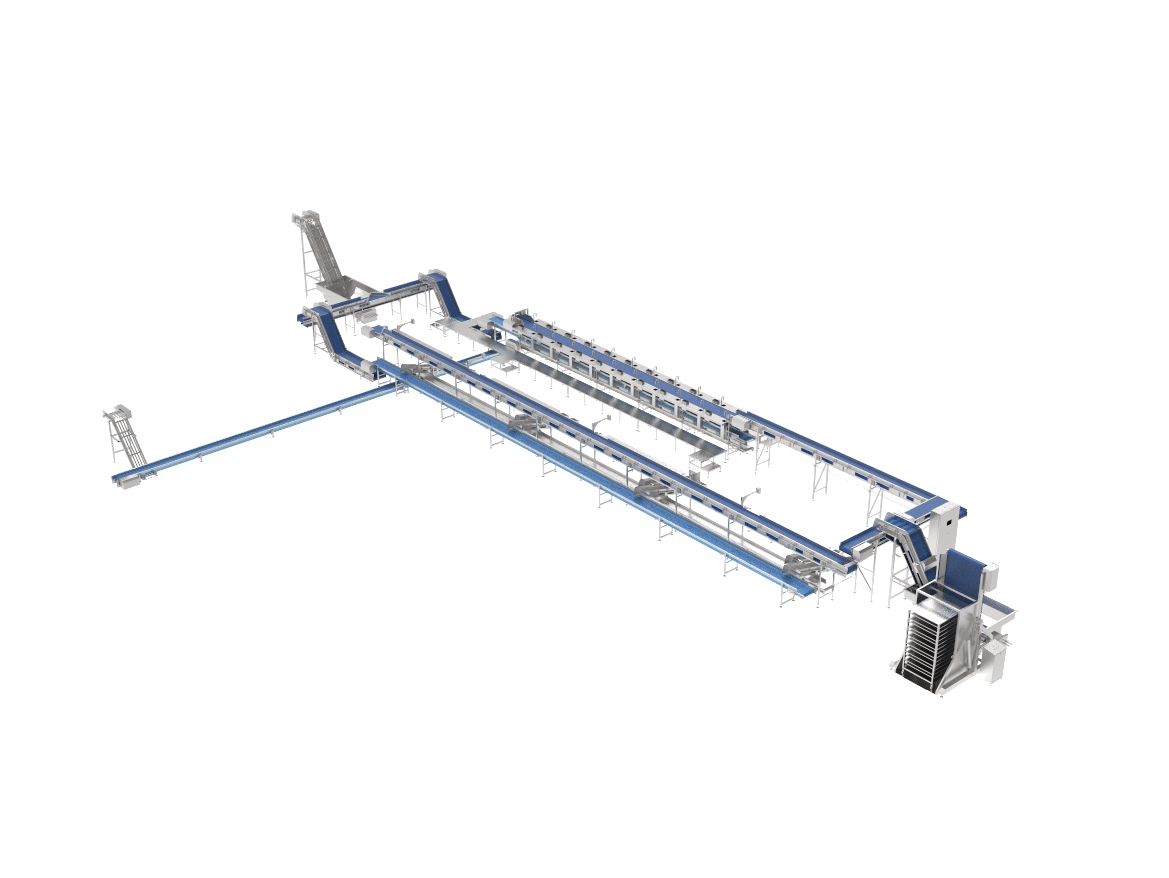

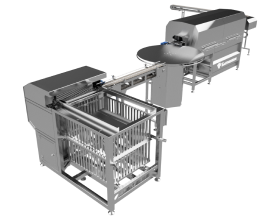

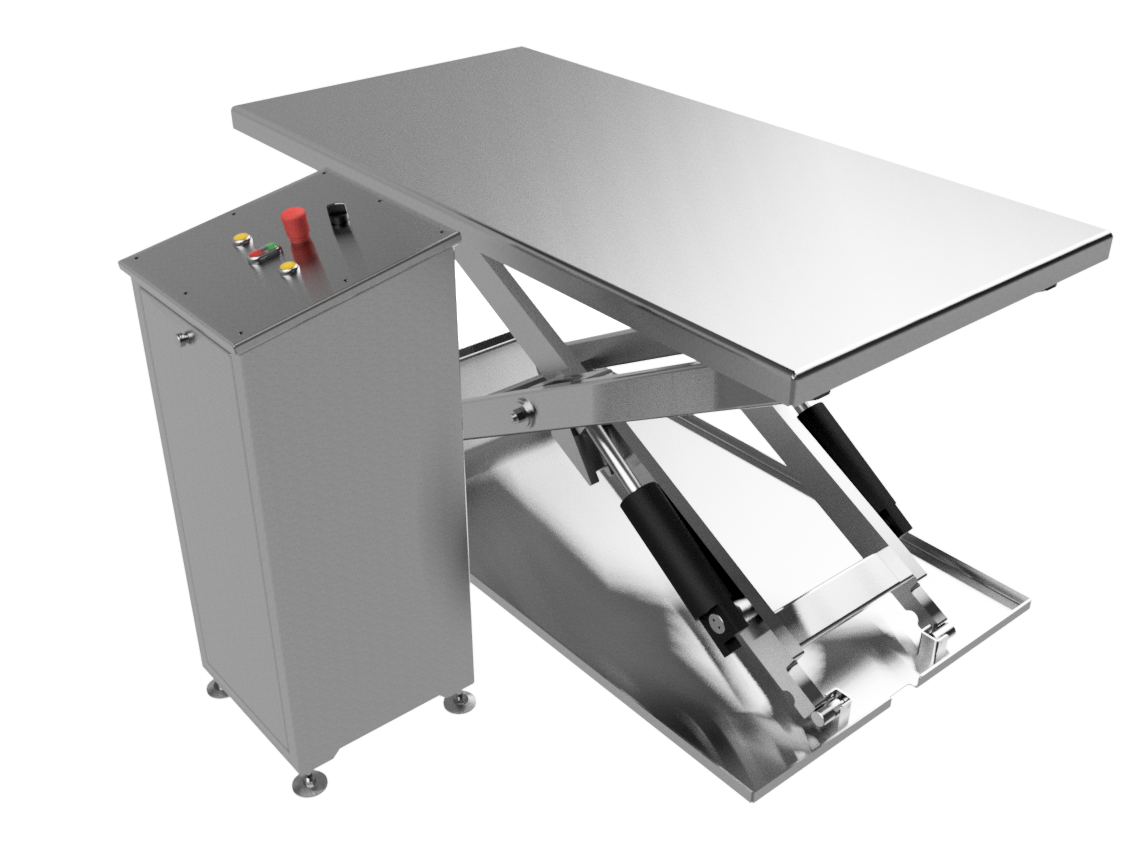

Semi-automatic basket loader

Semi-automatic basket loader

The algorithm of the device:

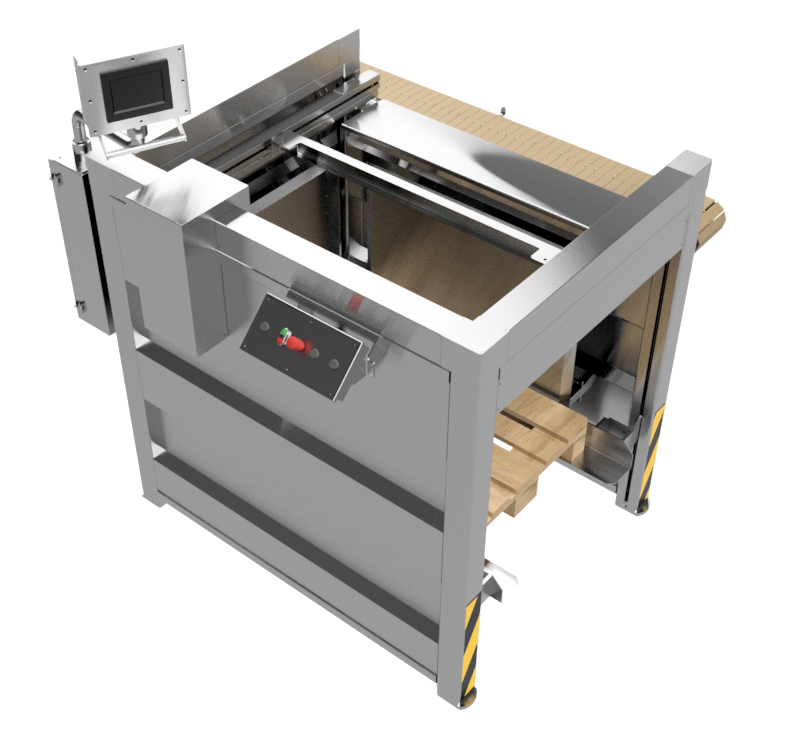

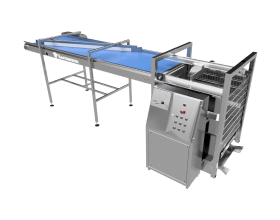

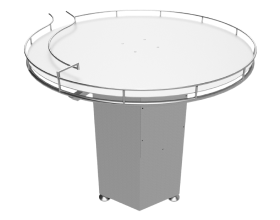

The can from the rotary table-orientator is conveyed to the receiving roller conveyor of the loader. The empty basket of an autoclave with a movable bottom, mounted on a trolley, is brought to the loader and is moved from the conveyor table of the trolley to the roller conveyor of the loader.

A row is formed between the pusher and the lifting limit plate. When the row is filled, the inductive presence sensor is activated and the pneumatic pusher moves the row to the lift platform, then returns to its original position until the next row is filled. When a layer is filled, the optical presence sensor is triggered and the cycle ends. Next, the operator lowers the pad, puts a gasket to load the next layer and presses the start button, starting the next cycle.

The algorithm of the device:

The can from the rotary table-orientator is conveyed to the receiving roller conveyor of the loader. The empty basket of an autoclave with a movable bottom, mounted on a trolley, is brought to the loader and is moved from the conveyor table of the trolley to the roller conveyor of the loader.

A row is formed between the pusher and the lifting limit plate. When the row is filled, the inductive presence sensor is activated and the pneumatic pusher moves the row to the lift platform, then returns to its original position until the next row is filled. When a layer is filled, the optical presence sensor is triggered and the cycle ends. Next, the operator lowers the pad, puts a gasket to load the next layer and presses the start button, starting the next cycle.

| METRIC | TARGET |

|---|---|

| Capacity | 100-120 b/min |

| Dimensions of the basket | 760×720×700 mm |

| Case material | stainless steel |

| Pusher drive | pneumatic cylinder |

| Hydraulic lift | pantograph |

RUS

RUS