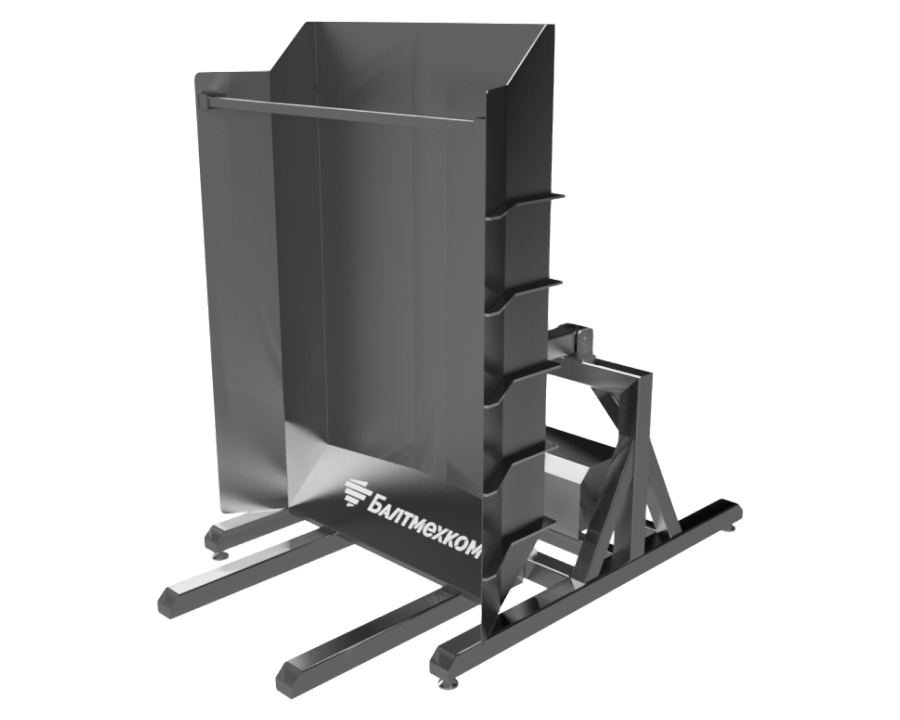

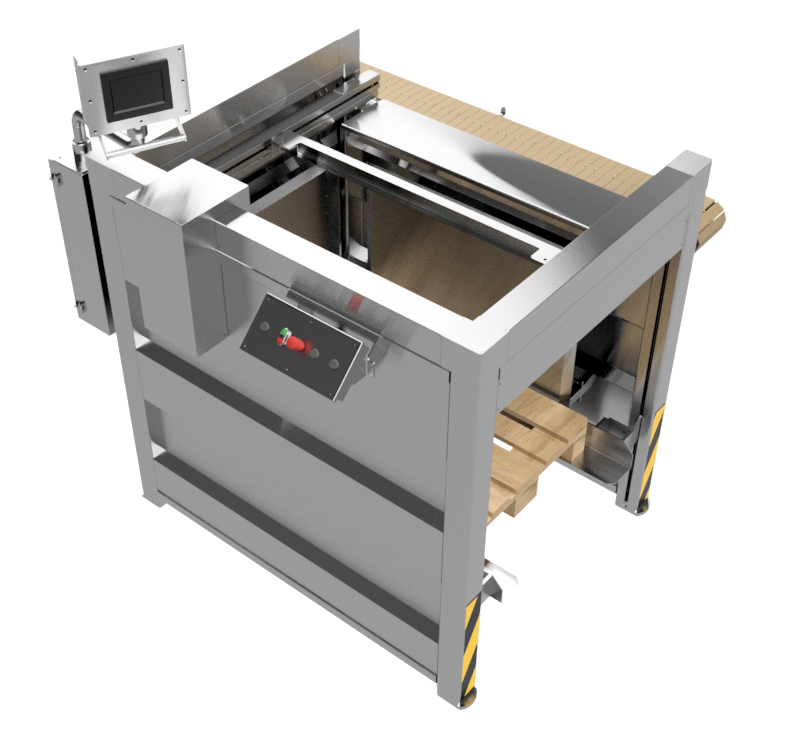

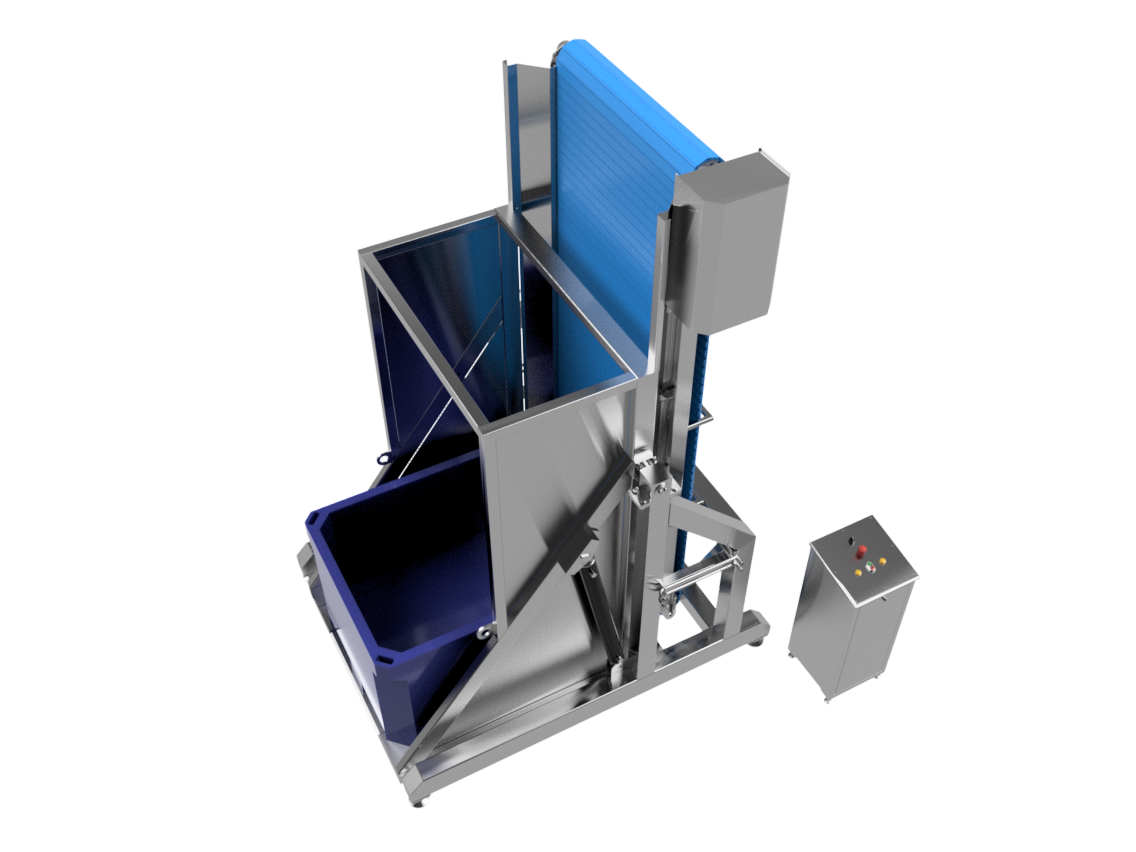

Cage tipper

Cage tipper

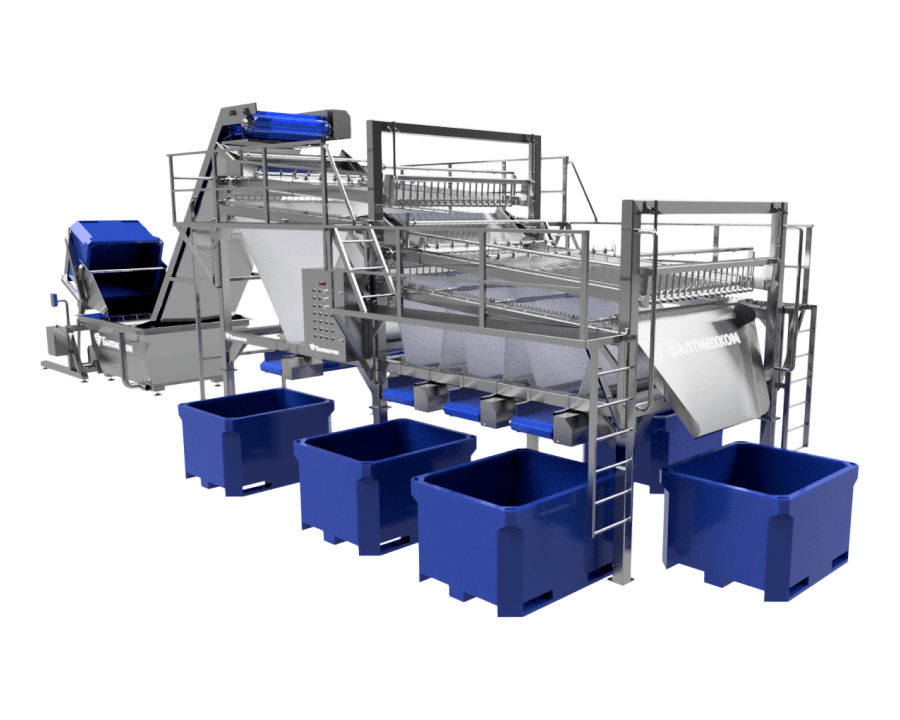

It is intended for unloading the contents of the cages with the products into storage bins, conveyors or other containers.

The device can be used autonomously for tilting the cages with the product, for example, after defrosting for further processing, as well as being integrated into technological lines for processing fish, meat, poultry, vegetables, etc.

Benefits:

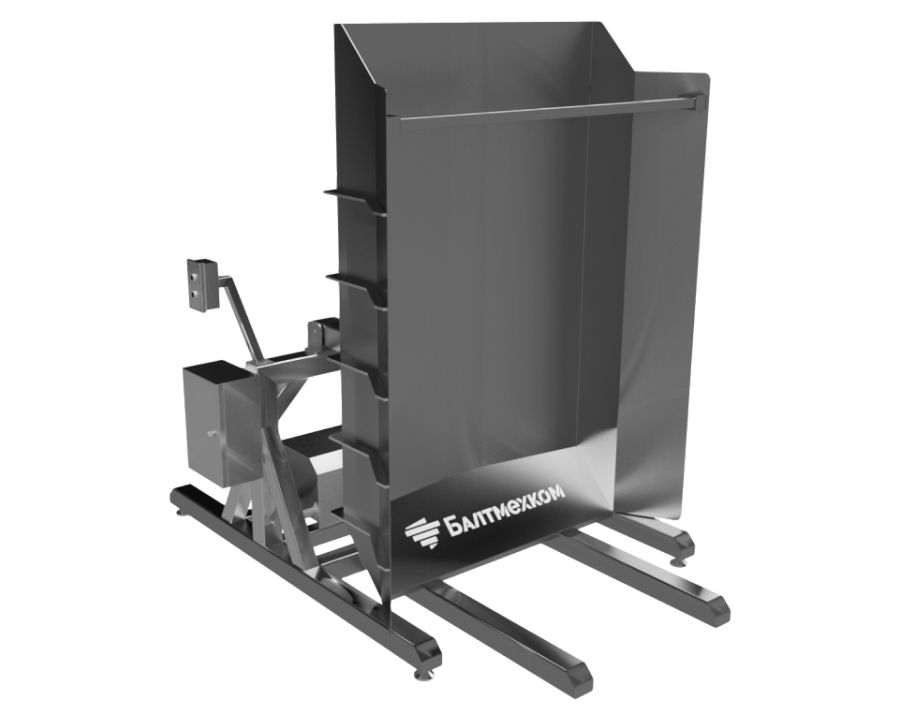

— Hygienic design: stainless steel construction. All parts are available for sanitization.

-Easy operation: control panel and buttons «top-bottom»

-Safety: hydraulic lifting scheme ensures the operation of the tipper only at the moment of pressing the button.

-The degree of protection of electrical equipment complies with IP65.

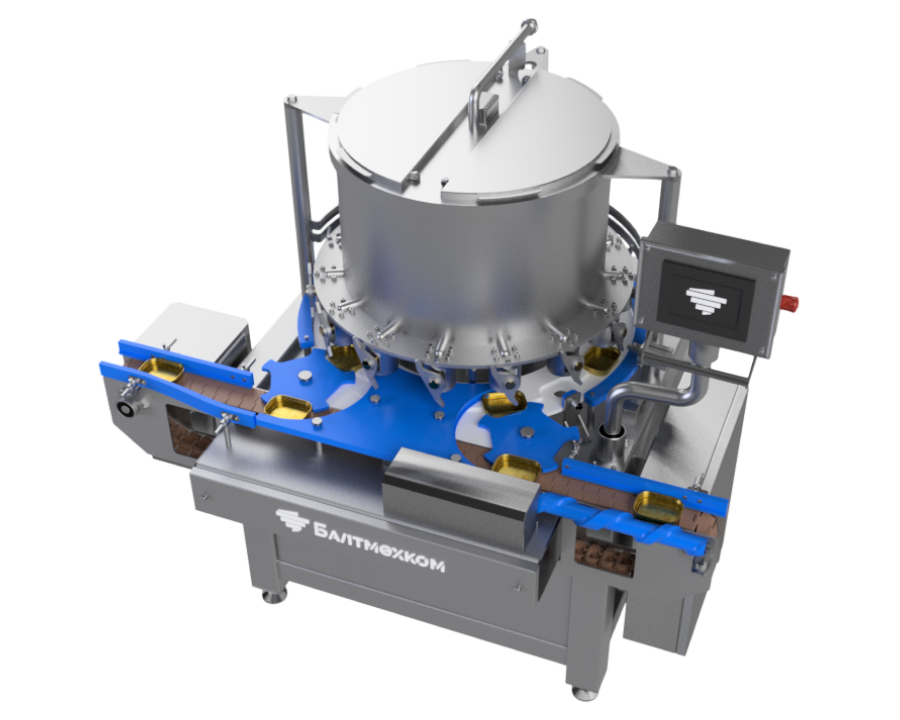

— Reliability: the use of components from leading manufacturers guarantee a long service life

It is intended for unloading the contents of the cages with the products into storage bins, conveyors or other containers.

The device can be used autonomously for tilting the cages with the product, for example, after defrosting for further processing, as well as being integrated into technological lines for processing fish, meat, poultry, vegetables, etc.

Benefits:

— Hygienic design: stainless steel construction. All parts are available for sanitization.

-Easy operation: control panel and buttons «top-bottom»

-Safety: hydraulic lifting scheme ensures the operation of the tipper only at the moment of pressing the button.

-The degree of protection of electrical equipment complies with IP65.

— Reliability: the use of components from leading manufacturers guarantee a long service life

| METRIC | TARGET |

|---|---|

| Overall dimensions | 2000×2400×2000 mm |

| Oil pressure | max 250 Kg/cm² |

| Loading capacity | 800 kg |

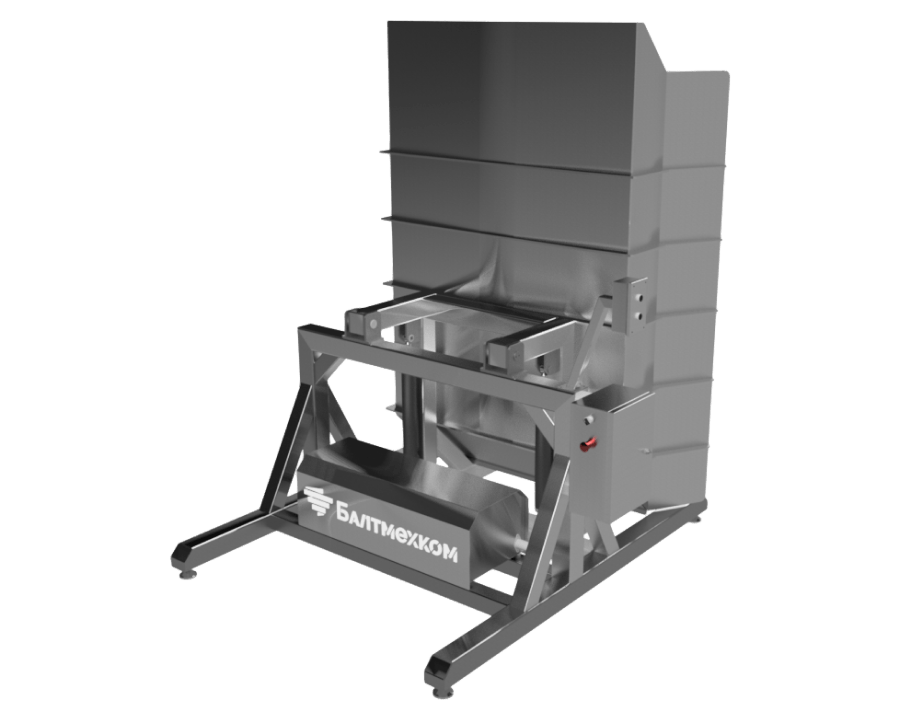

| Angle of rotation | 110 ° |

| Tipping height | 1000 mm |

| Cage dimensions | 2000×1200×1000 mm |

| Case material | stainless steel |

| Weight | not less than 400 kg |

RUS

RUS