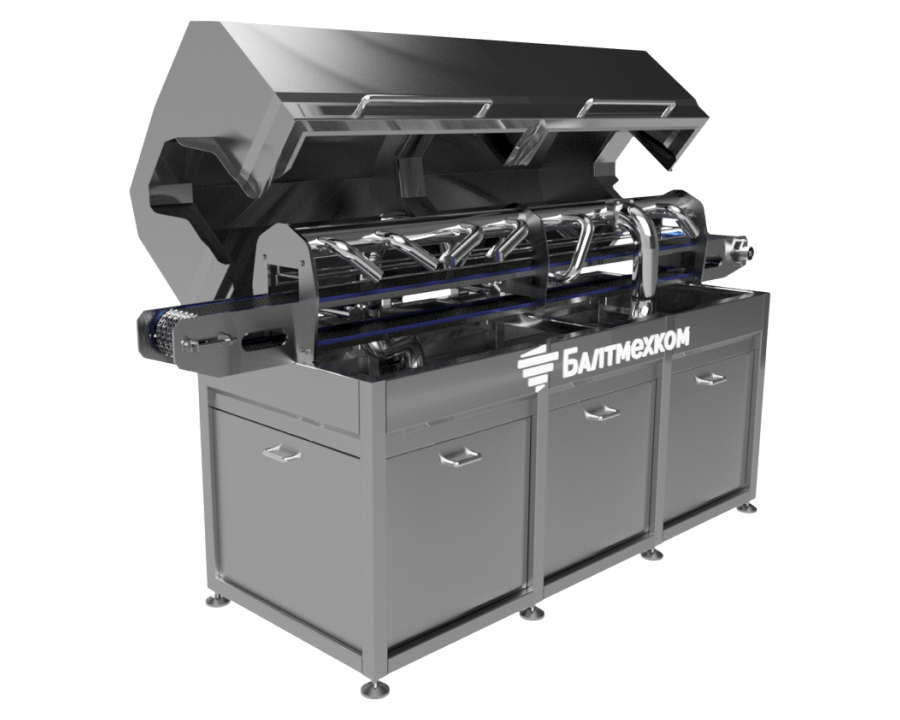

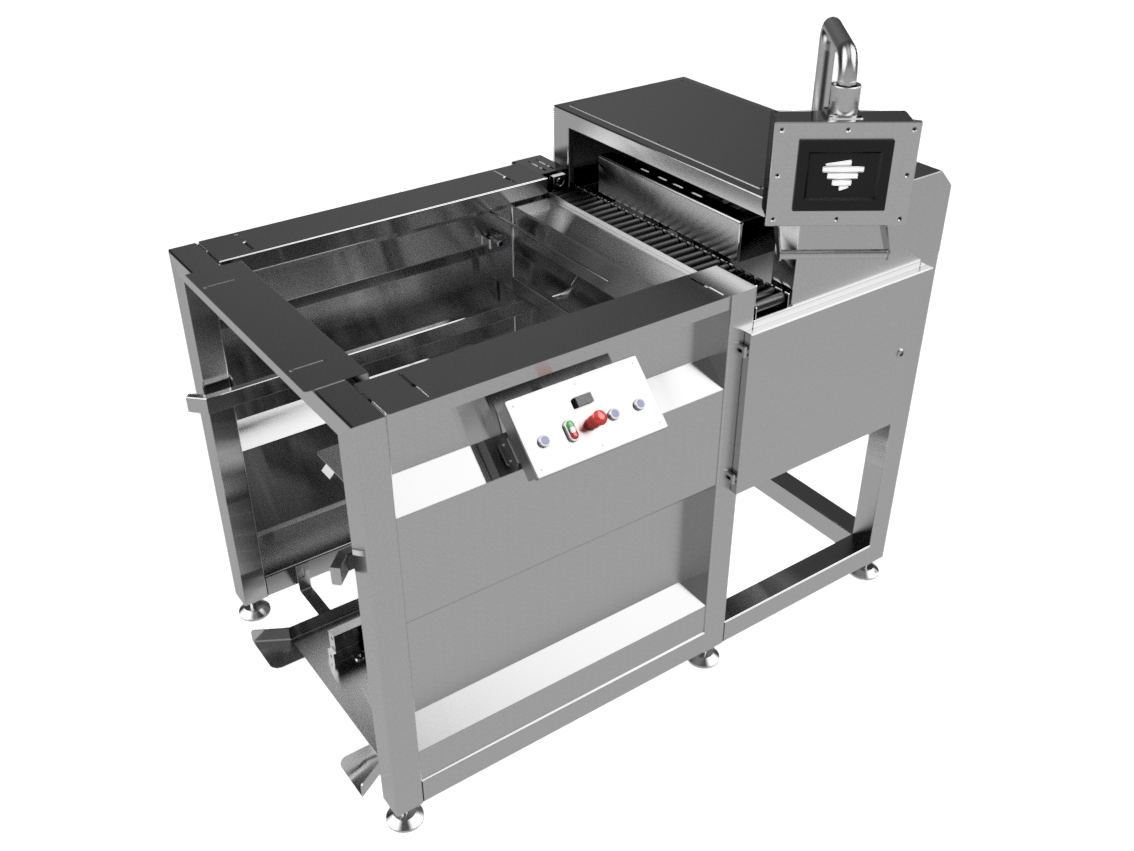

Can drying machine

Can drying machine

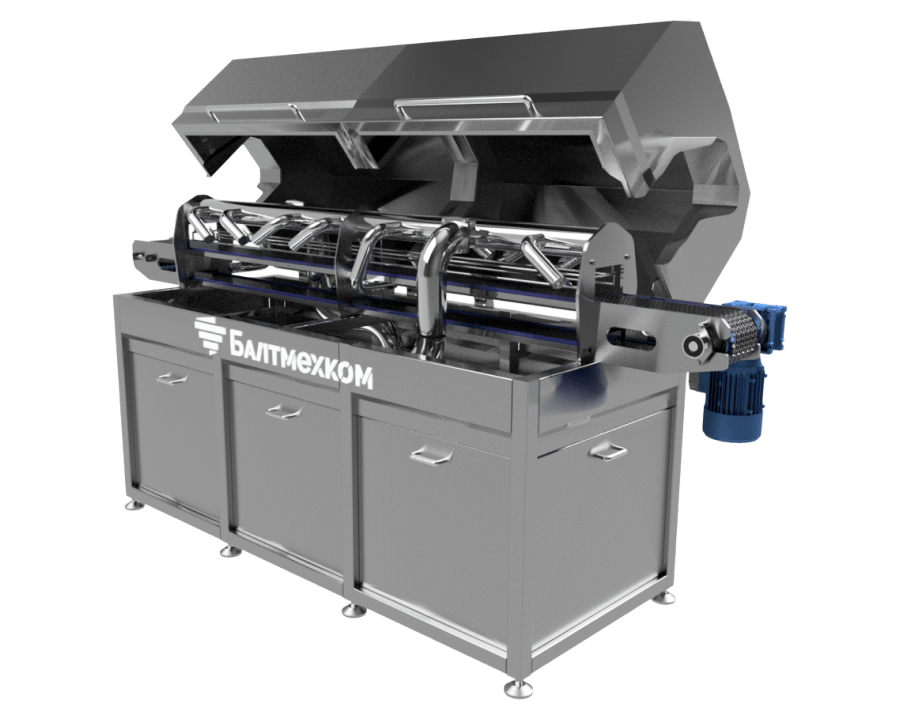

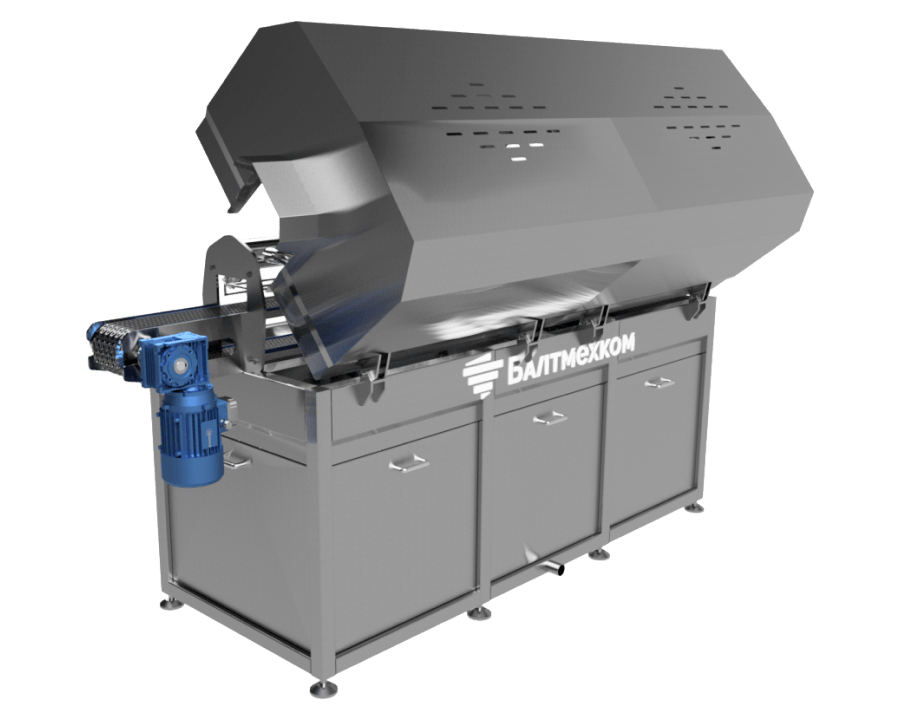

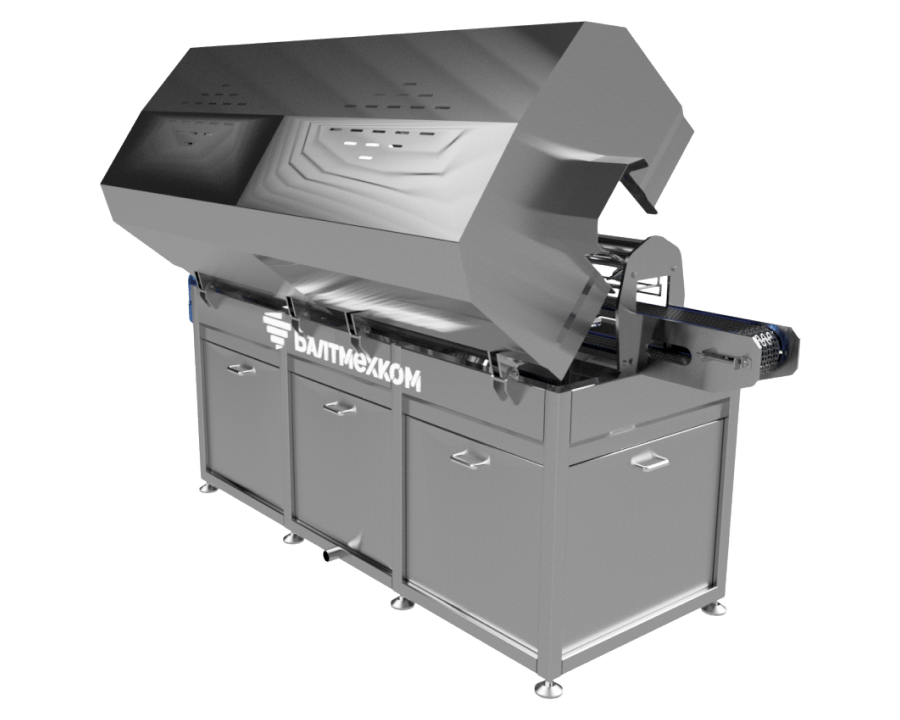

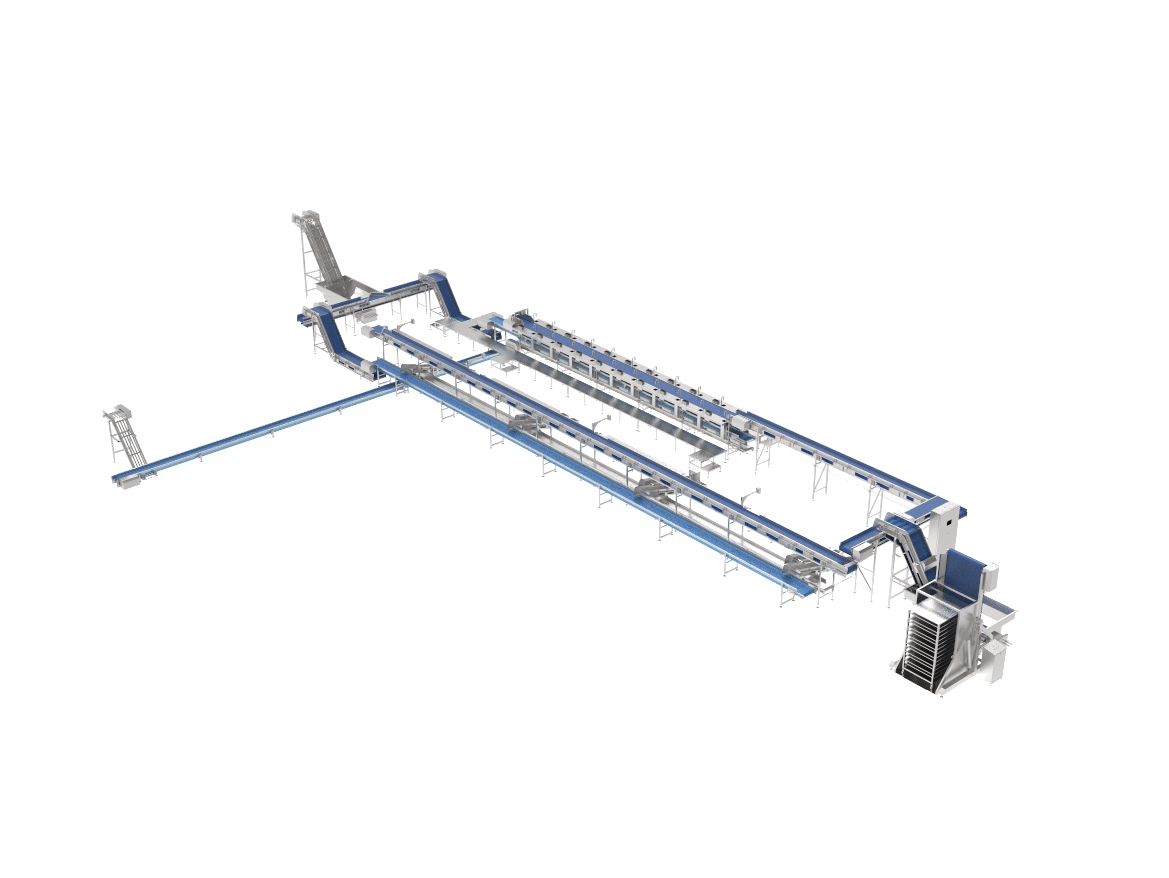

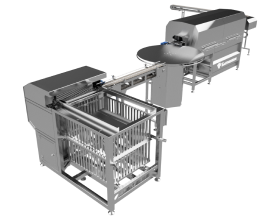

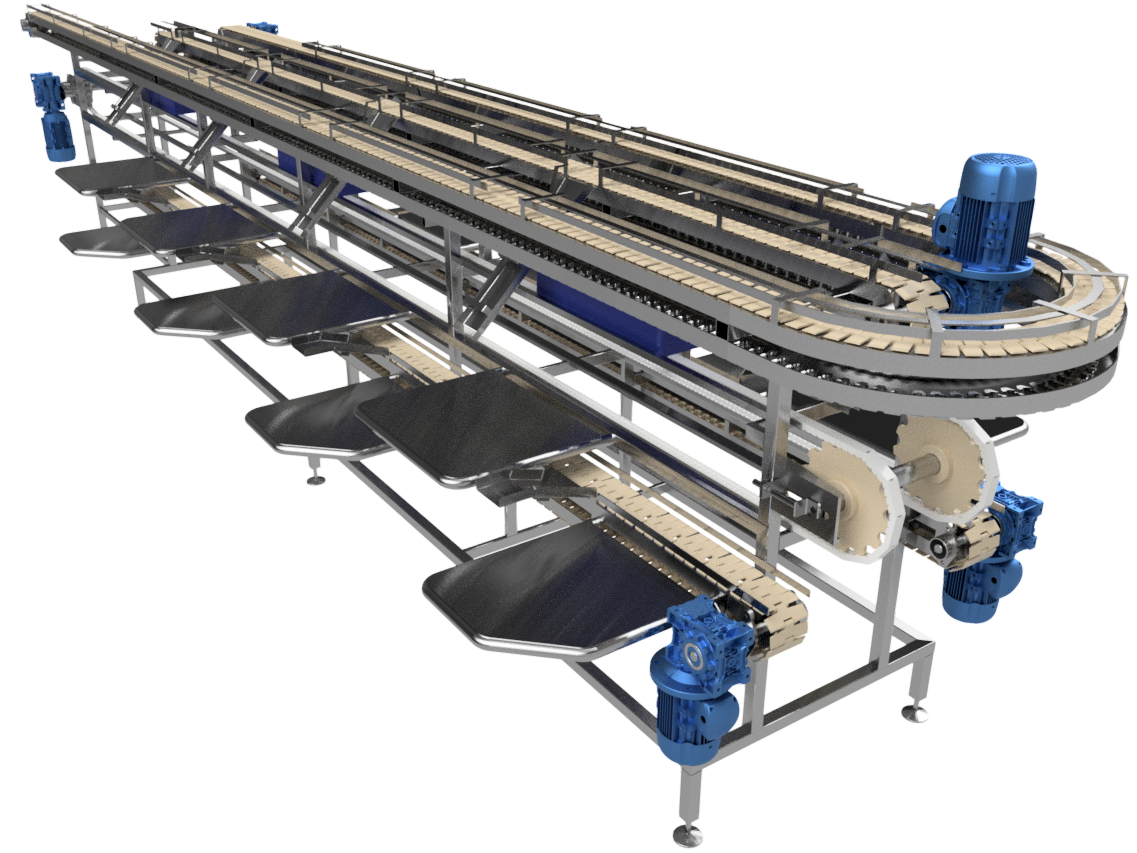

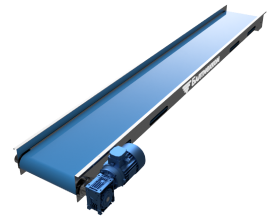

The machine is a linear type, designed to remove surface moisture from filled cans after seaming or sterilization. Used for tin cans number 2,3,6,8.

The process of removing moisture occurs through the active blowing shop air, using powerful vortex blowers that are installed at the bottom of the machine. Air blowing is carried out with air knives on all sides of the conveyor, and along the entire length of the drying chamber. The conveyor is equipped with side and top adjustable stoppers, thanks to which the machine is versatile and can be used for drying cans of various sizes.

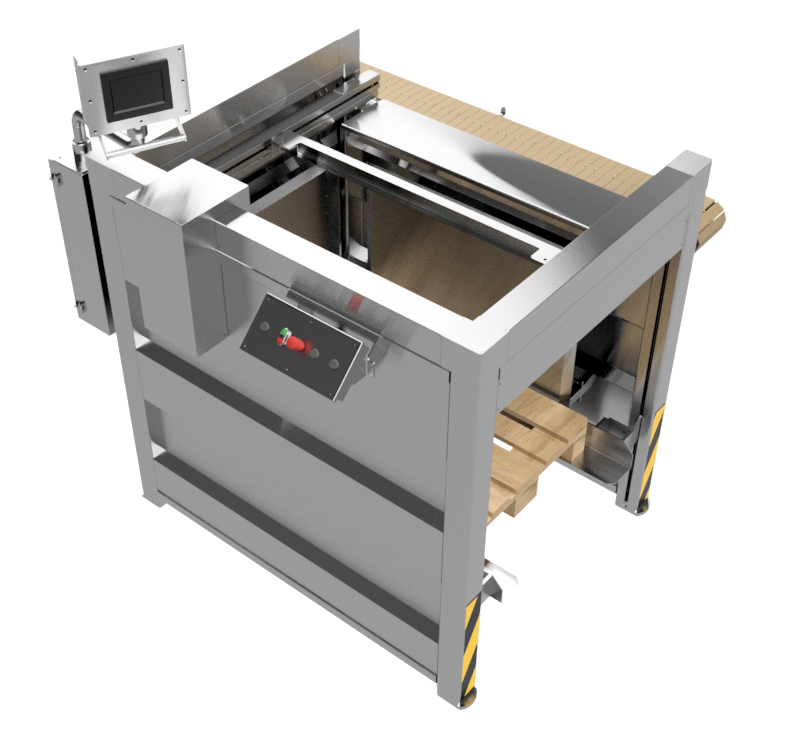

The equipment is controlled by an electronic control panel, which includes a PLC controller

The machine is a linear type, designed to remove surface moisture from filled cans after seaming or sterilization. Used for tin cans number 2,3,6,8.

The process of removing moisture occurs through the active blowing shop air, using powerful vortex blowers that are installed at the bottom of the machine. Air blowing is carried out with air knives on all sides of the conveyor, and along the entire length of the drying chamber. The conveyor is equipped with side and top adjustable stoppers, thanks to which the machine is versatile and can be used for drying cans of various sizes.

The equipment is controlled by an electronic control panel, which includes a PLC controller

| METRIC | TARGET |

|---|---|

| Capacity | 120 cans/min |

| Set power | 15,5 kW |

| Overall dimensions | 2600×800×1500mm |

| Case material | stainless steel |

RUS

RUS